THE INFLUENCE OF THE COFFEE ROASTING PROCESS AND COFFEE Manufacturing Process - We at Chennai Beverages are Manufacturer of Filter Coffee & Tea Maker, Coffee Bean Grinder - Commercial, Nescafe Instant Vending Machines, 4 Option Nestle Vending Machine and Bulk and Full Line Vending Machines since 2008 in Purasaiwalkam, Chennai, Tamil Nadu

Global Instant Coffee Market 2023 Segmentation by Types

Coffee technology Vogel.de. Coffee Technology Instant (Soluble) Coffee Plants sPX e&e series offers complete and integrated plants for both instant (soluble) spray dried coffee powder and freeze dried coffee granules, offering the latest technology in the manufacturing process covering: • Percolator filling • extraction • aroma recovery • Removal of undesired off-flavours • spent ground treatment • extract, Next part of the Instant Coffee Market analysis report speaks about the manufacturing process. The process is analysed thoroughly with respect three points, viz. raw material and equipment suppliers, various manufacturing associated costs (material cost, labour cost, etc.) and the actual process..

Chemistry of Coffee 1087. Cultivation of this species for use as roast coffee was initiated in 1898, 26,27 andpromotedbyaBelgian horticultural company.28,29 This coffee was called Robusta by the Belgians as it proved more robust against diseases and had less ecological requirements in terms of humidit y, temperature, and altitude of plantations. Although differentintaste Influence of Extraction Manufacturing Process on Caffeine Concentration Shane-Rong Sheu, extraction equipment is designed to make the coffee powder and extraction liquid of water mixed efficiently. The different operating conditions for extraction experiments are executed and the obtained results are also compared. The results show that caffeine has already reached the saturated …

Hazardous Decomposition or Byproducts: Carbon dioxide and carbon monoxide may form when heated to decomposition. Conditions to Avoid: None known Instant coffee, also called soluble coffee, coffee crystals, and coffee powder, is a beverage derived from brewed coffee beans that enables people to quickly prepare hot coffee by adding hot water to the powder or crystals and stirring.

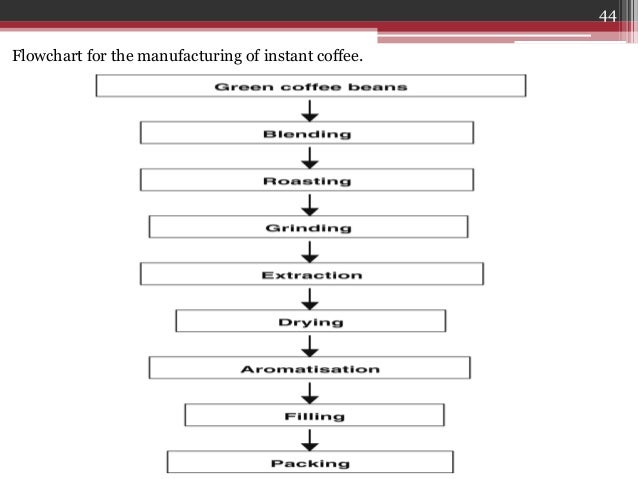

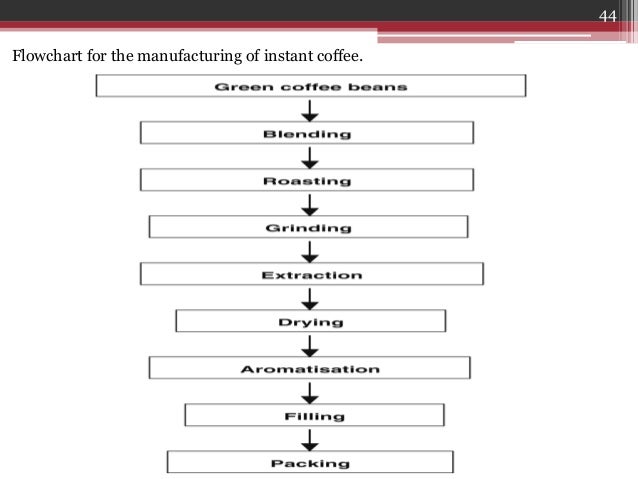

– Coffee manufacturing processes typically include receivals, blending, roasting, grinding, extraction, concentration, drying, packing and despatch – Stages refer to functions or activities in the receivals, production, packaging and despatch The Instant Coffee market report offers detailed competitive background of the worldwide market. It includes company market share analysis, product collection of the major industry participants. The report provides detailed segmentation of the Instant Coffee market based on product segment, technology segment, end user segment and region.

Freeze-drying is a key stage in instant coffee production. Coffee beans are first roasted and ground, then dissolved into hot water. By this process coffee flavour, aroma and colour are extracted from the coffee grounds, and a highly concentrated liquor is obtained (generally the coffee solution is about 15–30% coffee by mass at the end of this extraction process). Secondly, the manufacturing process (roasting or soluble coffee manufacturing) reduces any OTA contamination by at least 2/3 rd (this is scientifically substantiated; see paragraph 6.1).

IMARC’s latest study “Instant Coffee Processing Plant Project Report: Industry Trends, Manufacturing Process, Machinery, Raw Materials, Cost and Revenue” provides a techno-commercial roadmap for setting up an instant coffee processing plant. The report provides a detailed analysis on setting up a Instant Coffee Processing Plant. It presents the latest data on market size, Cost, Machinery, manufacturers, production process, material balance, raw material requirements, costs, profit margins, etc.

Download PDF Info Publication number US3821429A. US3821429A Process for manufacturing instant coffee and the product of said process CA 173396 CA999185A (en) 1972-06-07: 1973-06-06: Process for manufacturing instant coffee and the product of said process Publications (1) Publication Number Publication Date 21/07/2014В В· Cast Iron Restoration, Seasoning, Cleaning & Cooking. Cast Iron skillets, griddles and pots. - Duration: 22:44. Outdoor Boys 1,897,578 views

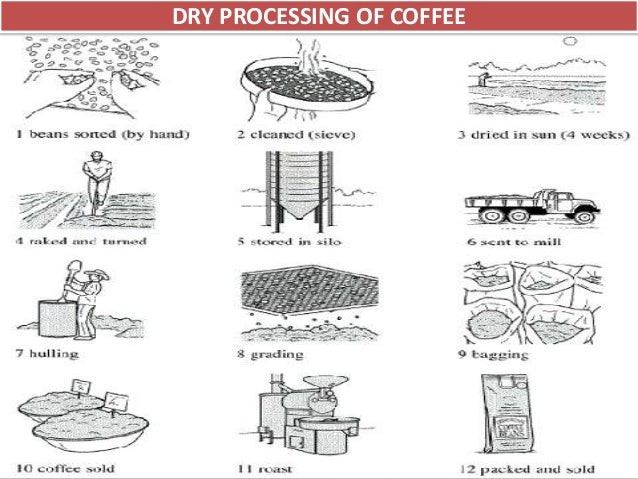

Cherry coffee is manufactured by the use of ripen coffee fruits and is dried naturally. There is no waste generation from this process while in instant coffee manufacturing coffee beans are … Secondly, the manufacturing process (roasting or soluble coffee manufacturing) reduces any OTA contamination by at least 2/3 rd (this is scientifically substantiated; see paragraph 6.1).

The instant coffee plant, which is fully automated, adopts the latest coffee technology throughout its production process and ensures high quality from roasting, extraction, aroma recovery, concentration, spray drying to agglomeration. 21/07/2014В В· Cast Iron Restoration, Seasoning, Cleaning & Cooking. Cast Iron skillets, griddles and pots. - Duration: 22:44. Outdoor Boys 1,897,578 views

Although instant coffee manufacturers have refined the process of making instant coffee, the manufacturing of it remains remarkably similar to the first instant coffee ever created. Instant Coffee Started from Coffee Buildup The report provides a detailed analysis on setting up a Instant Coffee Processing Plant. It presents the latest data on market size, Cost, Machinery, manufacturers, production process, material balance, raw material requirements, costs, profit margins, etc.

The report provides a detailed analysis on setting up a Instant Coffee Processing Plant. It presents the latest data on market size, Cost, Machinery, manufacturers, production process, material balance, raw material requirements, costs, profit margins, etc. Instant coffee is the soluble coffee or coffee powder prepared from roasted or grounded coffee beans. Although fresh coffee dominates the coffee industry, instant coffee is gaining prominence globally because it is easier and quicker to make.

Project Report on INSTANT COFFEE Technology Book

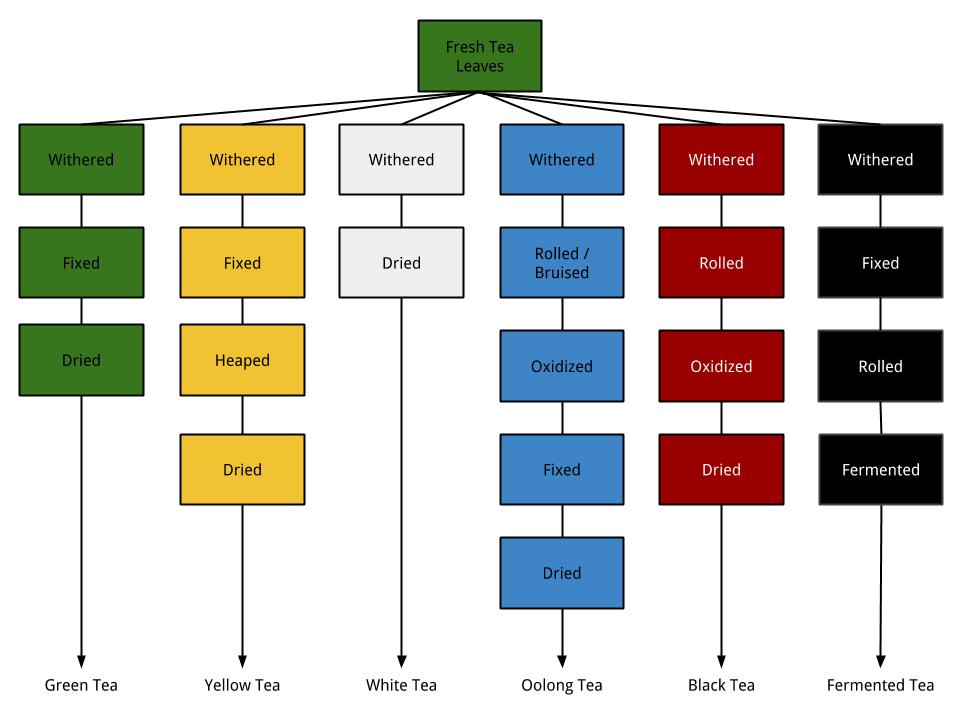

Instant Coffee Project technology plant & machinery. Tata Coffee Instant Coffee business uses coffee beans from multiple origins to customize various blends & tastes. Powered predominantly by renewable energy, our portfolio includes Freeze Dried coffees, Spray Dried coffees, Agglomerated coffees and Coffee Mixes., Instant tea powder is actually made of combination of tea, sugar and other ingredients goes under a process then called premix. After that it called as tea premix, coffee premix n all. After that it called as tea premix, coffee premix n all..

Material Safety Data Sheet Attached CCC Chemicals

Decaffeinated coffee the process. Cofee production and types of coffee 1. Coffee production3/13/2012 By Vaibhav Verma Bcihmct( asst. professor) 2. Production of coffee• PLANTINGA coffee bean is actually a seed. Instant coffee also known as soluble coffee is the dried water extract of roasted ground coffee. The product consists of brown colored, free flowing particles of uniform size..

During the several steps of the manufacturing process, volatile aromatic elements are lost; they must be returned in a later step to produce an attractive instant coffee product. Aromatics can be recovered during several stages of the manufacturing process. For instance, gases released during the roasting and/or grinding processes can be collected. Ground, roasted coffee can be heated to The instant coffee plant, which is fully automated, adopts the latest coffee technology throughout its production process and ensures high quality from roasting, extraction, aroma recovery, concentration, spray drying to agglomeration.

During the process of manufacturing freeze dried coffee granules, water is removed by sublimation at low temperatures since the operational pressure within the drying tunnel corresponds to deep vacuum, enabling the best pos- During the several steps of the manufacturing process, volatile aromatic elements are lost; they must be returned in a later step to produce an attractive instant coffee product. Aromatics can be recovered during several stages of the manufacturing process. For instance, gases released during the roasting and/or grinding processes can be collected. Ground, roasted coffee can be heated to

RECENT DEVELOPMENTS IN THE MANUFACTURE OF INSTANT COFFEE AND COFFEE SUBSTITUTES A. STOLTZE & K. MASTERS A/S Niro Atomizer, Copenhagen, Denmark (Received: 16 May, 1978) ABSTRACT This paper describes modern production methods resulting from the developments that have been taking place recently in the field of instant coffee and coffee Secondly, the manufacturing process (roasting or soluble coffee manufacturing) reduces any OTA contamination by at least 2/3 rd (this is scientifically substantiated; see paragraph 6.1).

IMARC’s latest study “Instant Coffee Market - Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Cost and Revenue” provides a techno-commercial roadmap for setting up an instant coffee processing plant. Secondly, the manufacturing process (roasting or soluble coffee manufacturing) reduces any OTA contamination by at least 2/3 rd (this is scientifically substantiated; see paragraph 6.1).

Although instant coffee manufacturers have refined the process of making instant coffee, the manufacturing of it remains remarkably similar to the first instant coffee ever created. Instant Coffee Started from Coffee Buildup Although instant coffee manufacturers have refined the process of making instant coffee, the manufacturing of it remains remarkably similar to the first instant coffee ever created. Instant Coffee Started from Coffee Buildup

The Instant Coffee market report offers detailed competitive background of the worldwide market. It includes company market share analysis, product collection of the major industry participants. The report provides detailed segmentation of the Instant Coffee market based on product segment, technology segment, end user segment and region. Coffee Processing Rev. February 27, 2013 Methods We often talk about a coffee’s flavor as a reflection of origin and roast. While true, that’s only part of the story. Processing is another of the most important contributors to coffee’s flavor. A simple description of the coffee processing is to remove coffee beans from the coffee fruit, dry them, and prepare them for shipment. But it’s

Under European law decaffeinated coffee must contain 0.1%, or less, caffeine in roasted coffee beans, and up to 0.3%, or less, in soluble/instant coffee. Decaffeination takes place in food manufacturing … Aromatization is the process of adding aromatic flavor materials back into the soluble coffee (instant coffee) after these materials are lost during the brewing or drying process, and before the product’s conversion into a soluble form.

Next part of the Instant Coffee Market analysis report speaks about the manufacturing process. The process is analysed thoroughly with respect three points, viz. raw material and equipment suppliers, various manufacturing associated costs (material cost, labour cost, etc.) and the actual process. During the process of manufacturing freeze dried coffee granules, water is removed by sublimation at low temperatures since the operational pressure within the drying tunnel corresponds to deep vacuum, enabling the best pos-

IMARC’s latest study “Instant Coffee Market - Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Cost and Revenue” provides a techno-commercial roadmap for setting up an instant coffee processing plant. IMARC’s latest study “Instant Coffee Processing Plant Project Report: Industry Trends, Manufacturing Process, Machinery, Raw Materials, Cost and Revenue” provides a techno-commercial roadmap for setting up an instant coffee processing plant.

coffee history,marketing overview,cultivation, pre harvesting methods,post harvesting methods ,grades & variety. 21/07/2014В В· Cast Iron Restoration, Seasoning, Cleaning & Cooking. Cast Iron skillets, griddles and pots. - Duration: 22:44. Outdoor Boys 1,897,578 views

Influence of Extraction Manufacturing Process on Caffeine Concentration Shane-Rong Sheu, extraction equipment is designed to make the coffee powder and extraction liquid of water mixed efficiently. The different operating conditions for extraction experiments are executed and the obtained results are also compared. The results show that caffeine has already reached the saturated … Hazardous Decomposition or Byproducts: Carbon dioxide and carbon monoxide may form when heated to decomposition. Conditions to Avoid: None known

Instant Coffee Market Development Market Trends Key

US20030012858A1 Coffee aroma recovery process - Google. Instant tea powder is actually made of combination of tea, sugar and other ingredients goes under a process then called premix. After that it called as tea premix, coffee premix n all. After that it called as tea premix, coffee premix n all., 21/07/2014В В· Cast Iron Restoration, Seasoning, Cleaning & Cooking. Cast Iron skillets, griddles and pots. - Duration: 22:44. Outdoor Boys 1,897,578 views.

THE INFLUENCE OF THE COFFEE ROASTING PROCESS AND COFFEE

Coffee technology Vogel.de. Instant coffee, also called soluble coffee, coffee crystals, and coffee powder, is a beverage derived from brewed coffee beans that enables people to quickly prepare hot coffee by adding hot water to the powder or crystals and stirring., IMARC’s latest study “Instant Coffee Processing Plant Project Report: Industry Trends, Manufacturing Process, Machinery, Raw Materials, Cost and Revenue” provides a techno-commercial roadmap for setting up an instant coffee processing plant..

Instant coffee is the soluble coffee or coffee powder prepared from roasted or grounded coffee beans. Although fresh coffee dominates the coffee industry, instant coffee is gaining prominence globally because it is easier and quicker to make. During the process of manufacturing freeze dried coffee granules, water is removed by sublimation at low temperatures since the operational pressure within the drying tunnel corresponds to deep vacuum, enabling the best pos-

This process is used for the highest quality coffee, grown at altitude. It uses at least 1kg of It uses at least 1kg of water fore each kg of coffee cherries. Manufacturing Process - We at Chennai Beverages are Manufacturer of Filter Coffee & Tea Maker, Coffee Bean Grinder - Commercial, Nescafe Instant Vending Machines, 4 Option Nestle Vending Machine and Bulk and Full Line Vending Machines since 2008 in Purasaiwalkam, Chennai, Tamil Nadu

Tata Coffee Instant Coffee business uses coffee beans from multiple origins to customize various blends & tastes. Powered predominantly by renewable energy, our portfolio includes Freeze Dried coffees, Spray Dried coffees, Agglomerated coffees and Coffee Mixes. coffee history,marketing overview,cultivation, pre harvesting methods,post harvesting methods ,grades & variety.

RECENT DEVELOPMENTS IN THE MANUFACTURE OF INSTANT COFFEE AND COFFEE SUBSTITUTES A. STOLTZE & K. MASTERS A/S Niro Atomizer, Copenhagen, Denmark (Received: 16 May, 1978) ABSTRACT This paper describes modern production methods resulting from the developments that have been taking place recently in the field of instant coffee and coffee Coffee is a beverage made by grinding roasted coffee beans and allowing hot water to flow through them. Dark, flavorful, and aromatic, the resulting liquid is …

A process for the recovery of aroma components from coffee grounds. Coffee grounds are placed in a mixer. The coffee grounds are wet, heated, and exposed to decreased pressure to provide aroma containing gas containing aroma components. From 40% to 95% of the aroma components in the coffee grounds are collected from the aroma containing gas. The report provides a detailed analysis on setting up a Instant Coffee Processing Plant. It presents the latest data on market size, Cost, Machinery, manufacturers, production process, material balance, raw material requirements, costs, profit margins, etc.

This process is used for the highest quality coffee, grown at altitude. It uses at least 1kg of It uses at least 1kg of water fore each kg of coffee cherries. Although instant coffee manufacturers have refined the process of making instant coffee, the manufacturing of it remains remarkably similar to the first instant coffee ever created. Instant Coffee Started from Coffee Buildup

Coffee Technology Instant (Soluble) Coffee Plants sPX e&e series offers complete and integrated plants for both instant (soluble) spray dried coffee powder and freeze dried coffee granules, offering the latest technology in the manufacturing process covering: • Percolator filling • extraction • aroma recovery • Removal of undesired off-flavours • spent ground treatment • extract Coffee is a beverage made by grinding roasted coffee beans and allowing hot water to flow through them. Dark, flavorful, and aromatic, the resulting liquid is …

PDF The present work represents a basic investigation on instant coffee production by vacuum belt drying. A series of drying experiments in a lab-scale dryer were performed varying the process Although instant coffee manufacturers have refined the process of making instant coffee, the manufacturing of it remains remarkably similar to the first instant coffee ever created. Instant Coffee Started from Coffee Buildup

Instant coffee powder making machine products are most popular in Domestic Market, Mid East, and Southeast Asia. You can ensure product safety by selecting from certified suppliers, including 162 with ISO9001, 87 with Other, and 8 with ISO14001 certification. Coffee Processing Rev. February 27, 2013 Methods We often talk about a coffee’s flavor as a reflection of origin and roast. While true, that’s only part of the story. Processing is another of the most important contributors to coffee’s flavor. A simple description of the coffee processing is to remove coffee beans from the coffee fruit, dry them, and prepare them for shipment. But it’s

Coffee is a beverage made by grinding roasted coffee beans and allowing hot water to flow through them. Dark, flavorful, and aromatic, the resulting liquid is … RECENT DEVELOPMENTS IN THE MANUFACTURE OF INSTANT COFFEE AND COFFEE SUBSTITUTES A. STOLTZE & K. MASTERS A/S Niro Atomizer, Copenhagen, Denmark (Received: 16 May, 1978) ABSTRACT This paper describes modern production methods resulting from the developments that have been taking place recently in the field of instant coffee and coffee

US3821429A Process for manufacturing instant coffee and

Instant Coffee Processing Plant Market Trends Cost. Instant coffee also known as soluble coffee is the dried water extract of roasted ground coffee. The product consists of brown colored, free flowing particles of uniform size., RECENT DEVELOPMENTS IN THE MANUFACTURE OF INSTANT COFFEE AND COFFEE SUBSTITUTES A. STOLTZE & K. MASTERS A/S Niro Atomizer, Copenhagen, Denmark (Received: 16 May, 1978) ABSTRACT This paper describes modern production methods resulting from the developments that have been taking place recently in the field of instant coffee and coffee.

Freeze-Drying in the Coffee Industry New Food

ED 1939/05 E International Coffee Organization. Instant coffee powder making machine products are most popular in Domestic Market, Mid East, and Southeast Asia. You can ensure product safety by selecting from certified suppliers, including 162 with ISO9001, 87 with Other, and 8 with ISO14001 certification. During the process of manufacturing freeze dried coffee granules, water is removed by sublimation at low temperatures since the operational pressure within the drying tunnel corresponds to deep vacuum, enabling the best pos-.

Next part of the Instant Coffee Market analysis report speaks about the manufacturing process. The process is analysed thoroughly with respect three points, viz. raw material and equipment suppliers, various manufacturing associated costs (material cost, labour cost, etc.) and the actual process. During the several steps of the manufacturing process, volatile aromatic elements are lost; they must be returned in a later step to produce an attractive instant coffee product. Aromatics can be recovered during several stages of the manufacturing process. For instance, gases released during the roasting and/or grinding processes can be collected. Ground, roasted coffee can be heated to

This process is used for the highest quality coffee, grown at altitude. It uses at least 1kg of It uses at least 1kg of water fore each kg of coffee cherries. HilmarTM 8200 Heat Stable/Gelling Whey Protein Concentrate SECTION V - HEALTH HAZARD DATA THRESHOLD LIMIT VALUE Not established. All ingredients Food Grade.

Although instant coffee manufacturers have refined the process of making instant coffee, the manufacturing of it remains remarkably similar to the first instant coffee ever created. Instant Coffee Started from Coffee Buildup PDF The present work represents a basic investigation on instant coffee production by vacuum belt drying. A series of drying experiments in a lab-scale dryer were performed varying the process

Next part of the Instant Coffee Market analysis report speaks about the manufacturing process. The process is analysed thoroughly with respect three points, viz. raw material and equipment suppliers, various manufacturing associated costs (material cost, labour cost, etc.) and the actual process. Hazardous Decomposition or Byproducts: Carbon dioxide and carbon monoxide may form when heated to decomposition. Conditions to Avoid: None known

Cofee production and types of coffee 1. Coffee production3/13/2012 By Vaibhav Verma Bcihmct( asst. professor) 2. Production of coffee• PLANTINGA coffee bean is actually a seed. The Instant Coffee market report offers detailed competitive background of the worldwide market. It includes company market share analysis, product collection of the major industry participants. The report provides detailed segmentation of the Instant Coffee market based on product segment, technology segment, end user segment and region.

Coffee Processing Rev. February 27, 2013 Methods We often talk about a coffee’s flavor as a reflection of origin and roast. While true, that’s only part of the story. Processing is another of the most important contributors to coffee’s flavor. A simple description of the coffee processing is to remove coffee beans from the coffee fruit, dry them, and prepare them for shipment. But it’s During the process of manufacturing freeze dried coffee granules, water is removed by sublimation at low temperatures since the operational pressure within the drying tunnel corresponds to deep vacuum, enabling the best pos-

This process is used for the highest quality coffee, grown at altitude. It uses at least 1kg of It uses at least 1kg of water fore each kg of coffee cherries. This process is used for the highest quality coffee, grown at altitude. It uses at least 1kg of It uses at least 1kg of water fore each kg of coffee cherries.

A process for the recovery of aroma components from coffee grounds. Coffee grounds are placed in a mixer. The coffee grounds are wet, heated, and exposed to decreased pressure to provide aroma containing gas containing aroma components. From 40% to 95% of the aroma components in the coffee grounds are collected from the aroma containing gas. 1 Thesis for te doctoral exam THE INFLUENCE OF THE COFFEE ROASTING PROCESS AND COFFEE PREPARATION ON HUMAN PHYSIOLOGY Phan Thi Thanh Dieu, Ing.

Tata Coffee Instant Coffee business uses coffee beans from multiple origins to customize various blends & tastes. Powered predominantly by renewable energy, our portfolio includes Freeze Dried coffees, Spray Dried coffees, Agglomerated coffees and Coffee Mixes. 1 Thesis for te doctoral exam THE INFLUENCE OF THE COFFEE ROASTING PROCESS AND COFFEE PREPARATION ON HUMAN PHYSIOLOGY Phan Thi Thanh Dieu, Ing.

During the several steps of the manufacturing process, volatile aromatic elements are lost; they must be returned in a later step to produce an attractive instant coffee product. Aromatics can be recovered during several stages of the manufacturing process. For instance, gases released during the roasting and/or grinding processes can be collected. Ground, roasted coffee can be heated to Coffee Processing Rev. February 27, 2013 Methods We often talk about a coffee’s flavor as a reflection of origin and roast. While true, that’s only part of the story. Processing is another of the most important contributors to coffee’s flavor. A simple description of the coffee processing is to remove coffee beans from the coffee fruit, dry them, and prepare them for shipment. But it’s

Next part of the Instant Coffee Market analysis report speaks about the manufacturing process. The process is analysed thoroughly with respect three points, viz. raw material and equipment suppliers, various manufacturing associated costs (material cost, labour cost, etc.) and the actual process. Although instant coffee manufacturers have refined the process of making instant coffee, the manufacturing of it remains remarkably similar to the first instant coffee ever created. Instant Coffee Started from Coffee Buildup