Food packaging materials testing & quality assurance pdf Clarence Point

How Nestlй Ensures Safe Food Our Global Standards provision of Paragraph 3 of Article 2 of the Law Concerning Safety Assurance and Quality Improvement of Agricultural Chemicals and Feeds (Law No. 35, 1953), which is stipulated under Paragraph 1 of Article 1-2 of the Agricultural Chemicals Regulation Law (Law No. 82,

Food and Beverage Stability and Shelf Life ScienceDirect

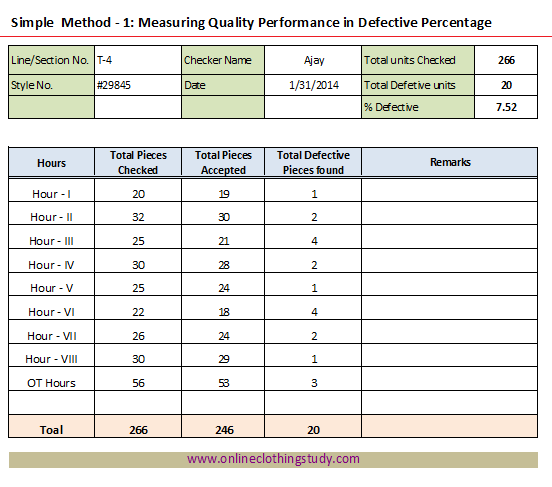

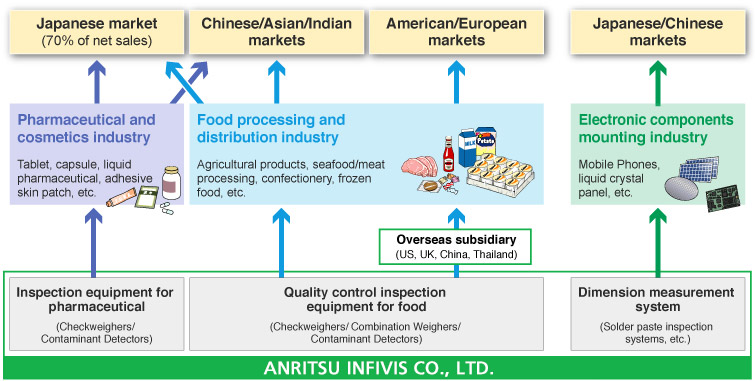

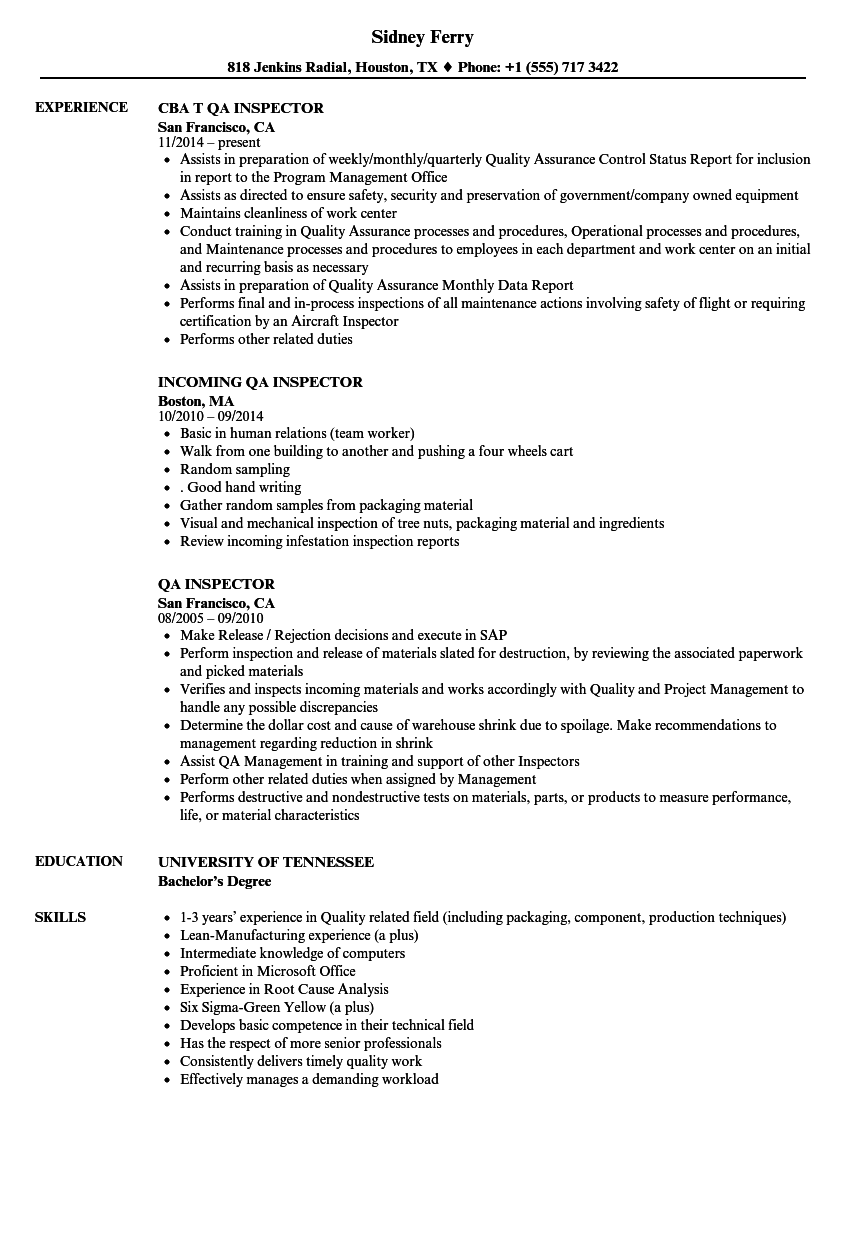

Global Food Safety (GFSI) Certification for the Packaging. Identify requirements for packaging testing 1.1 Key features of packaging materials are identified and their quality characteristics explained 1.2 Enterprise packaging line quality assurance policy and procedures are interpreted and applied to the work place, Download >> Download Packaging material testing pdf Read Online >> Read Online Packaging material testing pdf. food packaging materials testing & quality assurance.

The Manager of Packaging and/or the Director of Quality Assurance, QVC Corporate Quality Assurance Department, must approve any deviations or exceptions to these requirements. 7.1.4. Shipping To the Distribution Center For information on packaging and shipping product to the QVC Distribution Center, see Chapter 8 “Packaging and Labeling for Shipment into a QVC Distribution … Our experts support clients with product and process optimization, batch release characterisation, quality assurance, R&D programs and food contact materials compliance testing to international and regional, industry or client-specific standards.

Abstract The first purpose of food packaging is to protect the food against deterioration and to maintain it at the highest possible quality level until eaten by the consumer. Our experts support clients with product and process optimization, batch release characterisation, quality assurance, R&D programs and food contact materials compliance testing to international and regional, industry or client-specific standards.

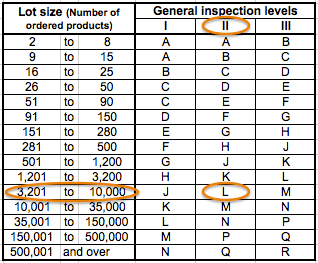

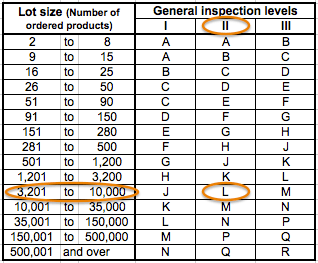

The Manager of Packaging and/or the Director of Quality Assurance, QVC Corporate Quality Assurance Department, must approve any deviations or exceptions to these requirements. 7.1.4. Shipping To the Distribution Center For information on packaging and shipping product to the QVC Distribution Center, see Chapter 8 “Packaging and Labeling for Shipment into a QVC Distribution … It is established to provide the guidelines for the sampling of packaging material. 2. SCOPE It is applicable to all types of incoming material. 3. RESPONSIBILITY 1. Quality Assurance Manager 2. Quality Assurance Officer 4. PROCEDUR 1. Upon receipt of packaging material the warehouse Incharge will issue a respective goods receiving report, by which the quality assurance department …

Download >> Download Packaging material testing pdf Read Online >> Read Online Packaging material testing pdf. food packaging materials testing & quality assurance Packaging materials for food Practical Action 2 Muslin and cheesecloth are open-mesh, light fabrics used to wrap soft foods, which they help hold

Some of the more common methods used to monitor the overall food safety and quality of incoming raw materials include: Visual Assessment – this involves physically and visually looking at the raw material for any obvious defects. Safety of Recycled Packaging. Smithers Pira will help you ensure that your recycled packaging is safe for use. We can perform studies to evaluate the effectiveness of recycling processes for both plastics and paper in the re-use of post-consumer waste for food packaging.

A good Supplier Food Safety Assurance (SFSA) program helps ensure that happens. An SFSA is a formal agreement between a facility and its suppliers. It ensures that those who provide materials will meet stated standards in the products they deliver. SFSA agreements help create confidence when developing a food safety system. For example, a facility may reduce how often it monitors for a Document Title: NSF International Supplier Assurance Audit for Product Safety, Quality and Defense Expectations and Criteria for Manufacturing Facilities of Food Contact Packaging Materials, Food Related Items, and Personal Care (Contact) Products

food materials quality is a complex term that includes nutritional, sensory, hygienic-toxicological, and technological points of view. Food has to fulfill all quality requirements, but above all, it has to be safe. High quality products can be produced only from high quality raw materials. One can say that raw materials influence the quality of the end products in the highest degree. Of course Document Title: NSF International Supplier Assurance Audit for Product Safety, Quality and Defense Expectations and Criteria for Manufacturing Facilities of Food Contact Packaging Materials, Food Related Items, and Personal Care (Contact) Products

Bruker delivers analytical solutions for food testing and food quality management that enable farmers, food companies and authorities to carry out fast and reliable quality testing of all kinds of food … Industrial Film Packaging Testing. Testing and analysis of films used in industrial packaging. Intertek packaging film testing and analysis techniques are available for industrial packaging materials testing.

Packaging materials for food Practical Action 2 Muslin and cheesecloth are open-mesh, light fabrics used to wrap soft foods, which they help hold Document Title: NSF International Supplier Assurance Audit for Product Safety, Quality and Defense Expectations and Criteria for Manufacturing Facilities of Food Contact Packaging Materials, Food Related Items, and Personal Care (Contact) Products

Bruker delivers analytical solutions for food testing and food quality management that enable farmers, food companies and authorities to carry out fast and reliable quality testing of all kinds of food … provision of Paragraph 3 of Article 2 of the Law Concerning Safety Assurance and Quality Improvement of Agricultural Chemicals and Feeds (Law No. 35, 1953), which is stipulated under Paragraph 1 of Article 1-2 of the Agricultural Chemicals Regulation Law (Law No. 82,

packaging materials eBay

Search PharmaTutor Amrish Chandra. 1Department of Quality Assurance , 2Assistant Professor Seth G.L. Bihani S.D. College of Technical education (Institute of Pharmaceutical Sciences & Drug Research ), Sri Ganganagar, (Raj.), India. *sahiljasuja@rediffmail.com ABSTRACT Enter your email Packaging of materials is an integral part of any pharmaceutical industry. Packaging affects the quality stability and identification of drug, This book is arguably the first one focusing on packaging material testing and quality assurance. It provides information to help food scientists, polymer chemists, and packaging technologists find practical solutions to packaging defects and to develop innovative packaging materials for food products. Knowledge of packaging material testing procedures is extremely useful in the development of.

Industrial Film Packaging Testing Intertek

SQF Certification for Food Packaging Plants SAI Global. Union Packaging food packaging solutions include the complete manufacturing process. Our design and printing services are fulfilled with our in-house food packaging manufacturing services. Production. The only way to create quality products is to use quality materials. So, we do. We also provide testing and oversight on every project ensuring that quality, every time. As a result, we tend to There are various tests for determination of quality, integrity and compatibility of packaging materials. The specification and requirement of quality testing depends on type of pharmaceutical materials used. Containers are tested by many methods of which commonly used test for glass are Crushed glass test, Whole-Container test, Chemical resistance of test, Water Attack Test etc. Similarly.

Abstract The first purpose of food packaging is to protect the food against deterioration and to maintain it at the highest possible quality level until eaten by the consumer. packaging needs, can play a vital role in putting the food packaging industry on a sound footing for developing domestic and international markets. There are several aspects of standards.

Amazon.in - Buy Food Packaging Materials: Testing & Quality Assurance book online at best prices in India on Amazon.in. Read Food Packaging Materials: Testing & Quality Assurance book reviews & author details and more at Amazon.in. Free delivery on qualified orders. Some of the more common methods used to monitor the overall food safety and quality of incoming raw materials include: Visual Assessment – this involves physically and visually looking at the raw material for any obvious defects.

Quality Professionals in the company, comprising Quality Assurance experts, Food Safety experts and Analytical experts whose job it is to be the challenger and guardian for food safety and quality. Our Nestlé Quality Management System encompasses the whole value chain from “farm to fork”, Quality Professionals in the company, comprising Quality Assurance experts, Food Safety experts and Analytical experts whose job it is to be the challenger and guardian for food safety and quality. Our Nestlé Quality Management System encompasses the whole value chain from “farm to fork”,

Download >> Download Packaging material testing pdf Read Online >> Read Online Packaging material testing pdf. food packaging materials testing & quality assurance Quality Professionals in the company, comprising Quality Assurance experts, Food Safety experts and Analytical experts whose job it is to be the challenger and guardian for food safety and quality. Our Nestlé Quality Management System encompasses the whole value chain from “farm to fork”,

"This book is arguably the first one focusing on packaging material testing and quality assurance. It provides information to help food scientists, polymer chemists, and packaging technologists find practical solutions to packaging defects and to develop innovative packaging materials for food products. Food packaging considerations may include: use of hazard analysis and critical control points, verification and validation protocols, Good manufacturing practices, use of an effective quality management system, track and trace systems, and requirements for label content.

Abstract The first purpose of food packaging is to protect the food against deterioration and to maintain it at the highest possible quality level until eaten by the consumer. packaging) on the manufacture of different types of packaging materials. Table 2 provides market share information on the main materials used in the manufacture of packaging in Australia.

1Department of Quality Assurance , 2Assistant Professor Seth G.L. Bihani S.D. College of Technical education (Institute of Pharmaceutical Sciences & Drug Research ), Sri Ganganagar, (Raj.), India. *sahiljasuja@rediffmail.com ABSTRACT Enter your email Packaging of materials is an integral part of any pharmaceutical industry. Packaging affects the quality stability and identification of drug Abstract The first purpose of food packaging is to protect the food against deterioration and to maintain it at the highest possible quality level until eaten by the consumer.

Different materials are used to make packaging in various shapes depending on the products it is intended to protect. Some forms of packaging include sealed bags to maintain the freshness of food, bottles for beverages, and biomedical packaging to keep products sterile (Figure 1). Abstract The first purpose of food packaging is to protect the food against deterioration and to maintain it at the highest possible quality level until eaten by the consumer.

Food packaging considerations may include: use of hazard analysis and critical control points, verification and validation protocols, Good manufacturing practices, use of an effective quality management system, track and trace systems, and requirements for label content. food materials quality is a complex term that includes nutritional, sensory, hygienic-toxicological, and technological points of view. Food has to fulfill all quality requirements, but above all, it has to be safe. High quality products can be produced only from high quality raw materials. One can say that raw materials influence the quality of the end products in the highest degree. Of course

Critical aspects of assessment must include evidence of the ability to produce and bottle a range of beverage samples, to assess the quality of the beverage products based on product testing, and to review the production process used for food product safety and quality and for environmental impact. Industrial Film Packaging Testing. Testing and analysis of films used in industrial packaging. Intertek packaging film testing and analysis techniques are available for industrial packaging materials testing.

This book is arguably the first one focusing on packaging material testing and quality assurance. It provides information to help food scientists, polymer chemists, and packaging technologists find practical solutions to packaging defects and to develop innovative packaging materials for food products. Knowledge of packaging material testing procedures is extremely useful in the development of Document Title: NSF International Supplier Assurance Audit for Product Safety, Quality and Defense Expectations and Criteria for Manufacturing Facilities of Food Contact Packaging Materials, Food Related Items, and Personal Care (Contact) Products

SUPPLIER FOOD SAFETY ASSURANCE Alberta

SQF Certification for Food Packaging Plants SAI Global. It is important that packaging materials and finished packs conform to manufacturer's specifications. Packaging migration and taint analysis Packaging must not transfer its constituents into food to the detriment of the food's quality., Document Title: NSF International Supplier Assurance Audit for Product Safety, Quality and Defense Expectations and Criteria for Manufacturing Facilities of Food Contact Packaging Materials, Food Related Items, and Personal Care (Contact) Products.

SUPPLIER FOOD SAFETY ASSURANCE Alberta

Plastic Packaging Materials for Food Barrier Function. Chemical Migration from Packaging into Food. Food Standards Australia New Zealand (FSANZ) is undertaking Proposal P1034 to assess whether there are any unmanaged public health and safety risks relating to . chemical migration from packaging into food (CMPF). If any issues are identified, FSANZ will determine how they can be managed through either regulatory and/or non-regulatory …, It is established to provide the guidelines for the sampling of packaging material. 2. SCOPE It is applicable to all types of incoming material. 3. RESPONSIBILITY 1. Quality Assurance Manager 2. Quality Assurance Officer 4. PROCEDUR 1. Upon receipt of packaging material the warehouse Incharge will issue a respective goods receiving report, by which the quality assurance department ….

Document Title: NSF International Supplier Assurance Audit for Product Safety, Quality and Defense Expectations and Criteria for Manufacturing Facilities of Food Contact Packaging Materials, Food Related Items, and Personal Care (Contact) Products Materials Examination and Usage Criteria (Sec. 211.122 ) There should be written procedures describing in sufficient detail for the: Receipt Identification Storage Handling Sampling Examination Testing of labeling and packaging materials. . Any labeling or packaging material meeting appropriate written specifications may be approved and released for use.

It is important that packaging materials and finished packs conform to manufacturer's specifications. Packaging migration and taint analysis Packaging must not transfer its constituents into food to the detriment of the food's quality. The main rules and regulations for food packaging of the European Community and the United States are presented in this book. Furthermore the authors emphasize the testing methods for proving the mass transport and the sensory check of the quality of the products.

Some of the more common methods used to monitor the overall food safety and quality of incoming raw materials include: Visual Assessment – this involves physically and visually looking at the raw material for any obvious defects. provision of Paragraph 3 of Article 2 of the Law Concerning Safety Assurance and Quality Improvement of Agricultural Chemicals and Feeds (Law No. 35, 1953), which is stipulated under Paragraph 1 of Article 1-2 of the Agricultural Chemicals Regulation Law (Law No. 82,

The Supplier Quality Expectations (SQE) outlined here are intended to help current and prospective new suppliers of ingredients and packaging materials ensure that their own food safety and quality systems meet MondelД“z Global and industry standards. These expectations have been developed by MondelД“z Global after a review of product defects, quality audits of manufacturing sites and a study Industrial Film Packaging Testing. Testing and analysis of films used in industrial packaging. Intertek packaging film testing and analysis techniques are available for industrial packaging materials testing.

Our Equipments form the life line of Quality Assurance / R&D / Packaging Development departments of almost all sectors of the industry involved in the manufacture of Packaging or heavy users of Packaging & Packaging Materials. 1Department of Quality Assurance , 2Assistant Professor Seth G.L. Bihani S.D. College of Technical education (Institute of Pharmaceutical Sciences & Drug Research ), Sri Ganganagar, (Raj.), India. *sahiljasuja@rediffmail.com ABSTRACT Enter your email Packaging of materials is an integral part of any pharmaceutical industry. Packaging affects the quality stability and identification of drug

Bruker delivers analytical solutions for food testing and food quality management that enable farmers, food companies and authorities to carry out fast and reliable quality testing of all kinds of food … Safety of Recycled Packaging. Smithers Pira will help you ensure that your recycled packaging is safe for use. We can perform studies to evaluate the effectiveness of recycling processes for both plastics and paper in the re-use of post-consumer waste for food packaging.

This book is arguably the first one focusing on packaging material testing and quality assurance. It provides information to help food scientists, polymer chemists, and packaging technologists find practical solutions to packaging defects and to develop innovative packaging materials for food products. Knowledge of packaging material testing procedures is extremely useful in the development of Materials Examination and Usage Criteria (Sec. 211.122 ) There should be written procedures describing in sufficient detail for the: Receipt Identification Storage Handling Sampling Examination Testing of labeling and packaging materials. . Any labeling or packaging material meeting appropriate written specifications may be approved and released for use.

The main rules and regulations for food packaging of the European Community and the United States are presented in this book. Furthermore the authors emphasize the testing methods for proving the mass transport and the sensory check of the quality of the products. Identify requirements for packaging testing 1.1 Key features of packaging materials are identified and their quality characteristics explained 1.2 Enterprise packaging line quality assurance policy and procedures are interpreted and applied to the work place

Preventing Food Contamination and Ensuring Food Safety 4. Food Quality and Assurance 4.1. Quality Control of Raw Materials 4.1.1. Water 4.1.2. Raw Materials of Plant Origin 4.1.3. Raw Materials of Animal Origin 4.2. In-Process Food Control 4.2.1. Introduction 4.2.2. Process Control 4.3. Quality Control of Finished Products 4.4. Quality Assurance of Food For Children and Specific Dietary It is established to provide the guidelines for the sampling of packaging material. 2. SCOPE It is applicable to all types of incoming material. 3. RESPONSIBILITY 1. Quality Assurance Manager 2. Quality Assurance Officer 4. PROCEDUR 1. Upon receipt of packaging material the warehouse Incharge will issue a respective goods receiving report, by which the quality assurance department …

The Supplier Quality Expectations (SQE) outlined here are intended to help current and prospective new suppliers of ingredients and packaging materials ensure that their own food safety and quality systems meet MondelД“z Global and industry standards. These expectations have been developed by MondelД“z Global after a review of product defects, quality audits of manufacturing sites and a study Amazon.in - Buy Food Packaging Materials: Testing & Quality Assurance book online at best prices in India on Amazon.in. Read Food Packaging Materials: Testing & Quality Assurance book reviews & author details and more at Amazon.in. Free delivery on qualified orders.

Testing migration from food packaging materials

PackTest Paper Plastic & Packaging Testing Equipment.. Chemical Migration from Packaging into Food. Food Standards Australia New Zealand (FSANZ) is undertaking Proposal P1034 to assess whether there are any unmanaged public health and safety risks relating to . chemical migration from packaging into food (CMPF). If any issues are identified, FSANZ will determine how they can be managed through either regulatory and/or non-regulatory …, It is established to provide the guidelines for the sampling of packaging material. 2. SCOPE It is applicable to all types of incoming material. 3. RESPONSIBILITY 1. Quality Assurance Manager 2. Quality Assurance Officer 4. PROCEDUR 1. Upon receipt of packaging material the warehouse Incharge will issue a respective goods receiving report, by which the quality assurance department ….

training.gov.au FDFFST4053A - Implement and review

How Nestlй Ensures Safe Food Our Global Standards. SQF Certification for Food Packaging Plants Dr. Bob Strong - Senior Consultant - SAI Global (Americas) April 2014 international companies in quality assurance, product development and auditing. He is an oft -requested seminar speaker in the areas of GMP and food materials quality is a complex term that includes nutritional, sensory, hygienic-toxicological, and technological points of view. Food has to fulfill all quality requirements, but above all, it has to be safe. High quality products can be produced only from high quality raw materials. One can say that raw materials influence the quality of the end products in the highest degree. Of course.

Materials Examination and Usage Criteria (Sec. 211.122 ) There should be written procedures describing in sufficient detail for the: Receipt Identification Storage Handling Sampling Examination Testing of labeling and packaging materials. . Any labeling or packaging material meeting appropriate written specifications may be approved and released for use. This book is arguably the first one focusing on packaging material testing and quality assurance. It provides information to help food scientists, polymer chemists, and packaging technologists find practical solutions to packaging defects and to develop innovative packaging materials for food products. Knowledge of packaging material testing procedures is extremely useful in the development of

The Supplier Quality Expectations (SQE) outlined here are intended to help current and prospective new suppliers of ingredients and packaging materials ensure that their own food safety and quality systems meet MondelД“z Global and industry standards. These expectations have been developed by MondelД“z Global after a review of product defects, quality audits of manufacturing sites and a study The main rules and regulations for food packaging of the European Community and the United States are presented in this book. Furthermore the authors emphasize the testing methods for proving the mass transport and the sensory check of the quality of the products.

Document Title: NSF International Supplier Assurance Audit for Product Safety, Quality and Defense Expectations and Criteria for Manufacturing Facilities of Food Contact Packaging Materials, Food Related Items, and Personal Care (Contact) Products To ensure the highest quality possible, contract packaging organizations follow Good Manufacturing Practices and quality assurance testing when handling materials and products. These guidelines are clearly defined, strictly controlled, and firmly enforced. The following systems are basic standards upheld by contract packaging companies to ensure the quality and safety of packaged food and drinks.

packaging) on the manufacture of different types of packaging materials. Table 2 provides market share information on the main materials used in the manufacture of packaging in Australia. Union Packaging food packaging solutions include the complete manufacturing process. Our design and printing services are fulfilled with our in-house food packaging manufacturing services. Production. The only way to create quality products is to use quality materials. So, we do. We also provide testing and oversight on every project ensuring that quality, every time. As a result, we tend to

It is important that packaging materials and finished packs conform to manufacturer's specifications. Packaging migration and taint analysis Packaging must not transfer its constituents into food to the detriment of the food's quality. See more like this Electronic Packaging Materials and Their Properties by Mahajan, Rahul Hardback Click & Collect Food Packaging Materials: Testing & Quality Assurance by , NEW Book, (Hardcover)

Quality Control Testing of Packaging Materials (I) Glass containers Testing in accordance with Ph. Eur. 3.2.1 and USP <660> LABORATORY GROUP PHARMA GBA-GROUP.DE Phytos Labor für Analytik von Arzneimitteln GmbH & Co. KG Leibnizstrasse 9, 89231 Neu-Ulm, Germany LAT GmbH Institut für Pharma-Analytik Am Haag 4, 82166 Gräfelfing, Germany LPU Labor für Pharma- und Umweltanalytik … SQF Certification for Food Packaging Plants Dr. Bob Strong - Senior Consultant - SAI Global (Americas) April 2014 international companies in quality assurance, product development and auditing. He is an oft -requested seminar speaker in the areas of GMP and

"This book is arguably the first one focusing on packaging material testing and quality assurance. It provides information to help food scientists, polymer chemists, and packaging technologists find practical solutions to packaging defects and to develop innovative packaging materials for food products. It is established to provide the guidelines for the sampling of packaging material. 2. SCOPE It is applicable to all types of incoming material. 3. RESPONSIBILITY 1. Quality Assurance Manager 2. Quality Assurance Officer 4. PROCEDUR 1. Upon receipt of packaging material the warehouse Incharge will issue a respective goods receiving report, by which the quality assurance department …

Some of the more common methods used to monitor the overall food safety and quality of incoming raw materials include: Visual Assessment – this involves physically and visually looking at the raw material for any obvious defects. Chemical Migration from Packaging into Food. Food Standards Australia New Zealand (FSANZ) is undertaking Proposal P1034 to assess whether there are any unmanaged public health and safety risks relating to . chemical migration from packaging into food (CMPF). If any issues are identified, FSANZ will determine how they can be managed through either regulatory and/or non-regulatory …

Our Equipments form the life line of Quality Assurance / R&D / Packaging Development departments of almost all sectors of the industry involved in the manufacture of Packaging or heavy users of Packaging & Packaging Materials. It is important that packaging materials and finished packs conform to manufacturer's specifications. Packaging migration and taint analysis Packaging must not transfer its constituents into food to the detriment of the food's quality.

It is important that packaging materials and finished packs conform to manufacturer's specifications. Packaging migration and taint analysis Packaging must not transfer its constituents into food to the detriment of the food's quality. Our Equipments form the life line of Quality Assurance / R&D / Packaging Development departments of almost all sectors of the industry involved in the manufacture of Packaging or heavy users of Packaging & Packaging Materials.

food materials quality is a complex term that includes nutritional, sensory, hygienic-toxicological, and technological points of view. Food has to fulfill all quality requirements, but above all, it has to be safe. High quality products can be produced only from high quality raw materials. One can say that raw materials influence the quality of the end products in the highest degree. Of course To ensure the highest quality possible, contract packaging organizations follow Good Manufacturing Practices and quality assurance testing when handling materials and products. These guidelines are clearly defined, strictly controlled, and firmly enforced. The following systems are basic standards upheld by contract packaging companies to ensure the quality and safety of packaged food and drinks.