Design of formwork for concrete structures pdf Boxers Creek

PDF Formwork For Concrete Structures zoesbakerycafe.ca The design of the final concrete structure may have a major effect on the ease of formwork construction and consequently, on the safety of people during construction.

Circular on Safety Requirements for Formwork Structures

Concrete Formwork Design Considerations Basis for. Temporary Structures Formwork for Concrete Formwork for Concrete . Tokyo Institute of Technology Advanced Topics in Civil Engineering - II Fall Semester 2005 Instructor: Kamran M. Nemati Subject: Temporary Structures Lesson 1: Introduction to Concrete Formwork and Vertical Formwork Design Overview The first lesson provides an overview on the basic structural wood design as it applies to, Action in the case of non-conformity of concrete structures, Report C519, 1999 Construct Guide to flat slab formwork and falsework, 2003 A guide to the safe transportation of formwork and falsework equipment, 2005 A guide to the safe use of formwork and falsework, 2008 Health and Safety Executive (HSE) Hand-vibration – The control of vibration at work regulations, 2005 The work at height.

13/01/2017 · After watching this video, you will see how quick and easy it is to plan formwork with Tekla Structures. Watch the new video of the Concrete Formwork Plannin... Formwork Code of Practice 2016 (PN11965)Page 6 of 54 1 Introduction 1.1 What is formwork? Formwork is a temporary structure that supports part or the whole of a permanent structure until it is

Several failures of falsework have focussed attention on the need for guidelines in the design and construction of falsework so as to achieve safety, reliability and economy in concrete construction. Theimportance of falsework at times, is not appreciated well. The Sectional Committee decided to evolve Guidelines for falsework for concrete structures. The purpose of these guidelines, in An experienced formwork designer should be consulted during the design of in-situ concrete structures to enable the health and safety risks during formwork construction and dismantling to be considered in the design.

Formwork for Concrete Structures, R.L. Peurifoy and Garold Oberlender, copyright 1995 by McGraw-Hill C. SELECTING AND SPECIFYING CONCRETE FORM PANELS General Virtually any Exterior type APA panel can be used for concrete formwork because all such panels are manufac-tured with waterproof glue. For concrete forming the plywood industry produces a special product called … Using fabric formwork, it is possible to cast architecturally interesting, optimised structures that use up to 40% less concrete than an equivalent strength prismatic section, thereby offering the

Formwork Code of Practice 2016 (PN11965)Page 6 of 54 1 Introduction 1.1 What is formwork? Formwork is a temporary structure that supports part or the whole of a permanent structure until it is Formwork by name means “The Mold” which means it is the casing into which the casting material, usually concrete, is poured to obtain the desired structural shape. In construction industry formwork is similar to a mold to cast concrete member in different shape and sizes using different types of materials such as timber, steel, aluminum, plastic, etc. Shuttering is a synonym term used for

CM 420 TEMPORARY STRUCTURES Lesson 2: Concrete Formwork Design Horizontal Formwork Design and Formwork Design Tables Overview The second lesson provides an overview on the basic structural wood design as it applies to concrete formwork. This lesson covers materials, methods and techniques associated with concrete formwork design and construction for slabs. This lesson … This book is divided into 18 Chapters. The first three chapters provide an introduction to formwork, materials for formwork, and design basics for formwork.

Generally design of formwork even though it is a temporary structure, the same design Principles used for permanent structure will be used with some assumptions. 2 emissions8, providing further impetus for the design of optimised structures. Concrete volume savings in fabric formed beams, when compared to an equivalent strength prismatic member, of 40% have already been achieved9,10, illustrating the potential for fabric formwork to reduce the embodied energy of new building structures. Yet fabric formwork does not simply facilitate reductions in

This book is divided into 18 Chapters. The first three chapters provide an introduction to formwork, materials for formwork, and design basics for formwork. Formwork for Concrete Structures, R.L. Peurifoy and Garold Oberlender, copyright 1995 by McGraw-Hill C. SELECTING AND SPECIFYING CONCRETE FORM PANELS General Virtually any Exterior type APA panel can be used for concrete formwork because all such panels are manufac-tured with waterproof glue. For concrete forming the plywood industry produces a special product called …

Design for the joist table presented above includes a 4 kPa allowance for stacked materials in accordance with AS 3610. Where the stacked material load is reduced in accordance with AS 3610, then spans used may be larger than those given above - refer formwork designer. Formwork for concrete SECTION 1 GENERAL 1.1 SCOPE This Standard sets out requirements for the design, fabrication, erection and stripping of formwork, as well as the specification, evaluation and repair of the quality of the formed concrete surface and the influence of this activity on the design and construction of an in situ concrete structure. Design by testing is considered separately, the

Download Formwork for Concrete Structures By Robert L Peurifoy and Garold D Oberlender – This book is written for architects, engineers, and constructors who are responsible for designing and/or building formwork and temporary structures during the construction process. Design and building concrete formwork effectively requires a basic understanding of how concrete behaves as it exerts pressure on formwork. Concrete exerts lateral pressure on the formwork.

The design of formwork has been divided into two chapters, one focusing on bending, shear, and deflection of wall, slab, and column formwork members, and a second focusing on shoring and bracing members. Bridge formwork considerations have been moved into a separate chapter. A new chapter summarizing the recommendations of ACI 347.3R-13, “Guide to Formed Concrete Surfaces,” has … Formwork by name means “The Mold” which means it is the casing into which the casting material, usually concrete, is poured to obtain the desired structural shape. In construction industry formwork is similar to a mold to cast concrete member in different shape and sizes using different types of materials such as timber, steel, aluminum, plastic, etc. Shuttering is a synonym term used for

Concrete Formwork Design nishkian.com

Formwork Codes & Design Key Points - The Masterbuilder. The design of the final concrete structure can have a major effect on the ease of formwork construction, and consequently, on the safety of persons during construction. Generally, the more basic and simple the final concrete structure, the safer it is to erect., Formwork For Concrete Structures PDF Download A Necessary Topic For Construction Engineers Formwork For Concrete Structures Seems To Lack A Penetrating Insight Into The Explanation Of Concrete Formwork Design Although Not A Bad Book It Is Loaded With Lots Of Illustrations Tables Photographs There Are Some Equations And Calculation Examplesdramatically Slash The Cost Of Formwork Design ….

5.0 FALSEWORK DESIGN ANALYSIS AND INSPECTION. Concrete formwork is the temporary structure built to support and confine concrete until it hardens and it is commonly broken into two categories: formwork and shoring. Formwork refers to vertical forms used to form walls and columns whereas shoring refers to horizontal formwork …, Temporary structures **formwork** Design Loads on Forms: The American Concrete Institute (ACI) publishes a document called “ACI 347 – Guide to Formwork for Concrete. ” 1) Form Dead Loads – the actual weight of the forms, plus the weight of fresh (i.e., wet) concrete. 2) Form Live Loads – the weight of workers, equipment and material storage. The minimum live load is 50 psf, while a.

Circular on Safety Requirements for Formwork Structures

Concrete Formwork Planning Made Quick and Easy YouTube. The design of the final concrete structure can have a major effect on the ease of formwork construction, and consequently, on the safety of persons during construction. Generally, the more basic and simple the final concrete structure, the safer it is to erect. Formwork is considered to be the material or form that provides the shape to the concrete placement and the immediate structural system that supports the form. Falsework is the structural system that supports the formwork..

Some aspects of formwork design •Collection of initial data about the building site and structure •Preliminary choice of formwork type •Determination of formwork costs •Choice of additional equipment •Design – determination of loads, calculation… 22 Rak-82.2121 Production Technology of Concrete Structures (4 cr) Fahim Al-Neshawy & Esko Sistonen Autumn 2015 Loads and pressures Formwork for Concrete Structures, R.L. Peurifoy and Garold Oberlender, copyright 1995 by McGraw-Hill C. SELECTING AND SPECIFYING CONCRETE FORM PANELS General Virtually any Exterior type APA panel can be used for concrete formwork because all such panels are manufac-tured with waterproof glue. For concrete forming the plywood industry produces a special product called …

This book is divided into 18 Chapters. The first three chapters provide an introduction to formwork, materials for formwork, and design basics for formwork. General: Design and construct formwork so that the concrete, when cast in the forms, will have the required dimensions, shape, profile, location and surface finish. Allow for dimensional changes, deflections and cambers

Formwork For Concrete Structures PDF Download A Necessary Topic For Construction Engineers Formwork For Concrete Structures Seems To Lack A Penetrating Insight Into The Explanation Of Concrete Formwork Design Although Not A Bad Book It Is Loaded With Lots Of Illustrations Tables Photographs There Are Some Equations And Calculation Examplesdramatically Slash The Cost Of Formwork Design … Generally design of formwork even though it is a temporary structure, the same design Principles used for permanent structure will be used with some assumptions.

Formwork in construction is the use of support structures and moulds to create structures out of concrete which is poured into the moulds. Formwork can be made using moulds out of steel, wood, aluminium and/or prefabricated forms. Formwork is an ancillary construction, used as a mould for a structure. Into this mould, fresh concrete is placed only to harden subsequently. The construction of The design of the final concrete structure can have a major effect on the ease of formwork construction, and consequently, on the safety of persons during construction. Generally, the more basic and simple the final concrete structure, the safer it is to erect.

A. Design, engineer and construct formwork, shoring, and bracing to conform to design and code requirements; resultant concrete to required shape, line and dimension. General: Design and construct formwork so that the concrete, when cast in the forms, will have the required dimensions, shape, profile, location and surface finish. Allow for dimensional changes, deflections and cambers

Formwork For Concrete Structures PDF Download A Necessary Topic For Construction Engineers Formwork For Concrete Structures Seems To Lack A Penetrating Insight Into The Explanation Of Concrete Formwork Design Although Not A Bad Book It Is Loaded With Lots Of Illustrations Tables Photographs There Are Some Equations And Calculation Examplesdramatically Slash The Cost Of Formwork Design … 2 emissions8, providing further impetus for the design of optimised structures. Concrete volume savings in fabric formed beams, when compared to an equivalent strength prismatic member, of 40% have already been achieved9,10, illustrating the potential for fabric formwork to reduce the embodied energy of new building structures. Yet fabric formwork does not simply facilitate reductions in

Formwork For Concrete Structures PDF Download A Necessary Topic For Construction Engineers Formwork For Concrete Structures Seems To Lack A Penetrating Insight Into The Explanation Of Concrete Formwork Design Although Not A Bad Book It Is Loaded With Lots Of Illustrations Tables Photographs There Are Some Equations And Calculation Examplesdramatically Slash The Cost Of Formwork Design … 25 A formwork structure should only be dismantled after the concrete has sufficiently set and after a period of time as determined by the Qualified Person (Design) or otherwise, with reference from SS …

Design and building concrete formwork effectively requires a basic understanding of how concrete behaves as it exerts pressure on formwork. Concrete exerts lateral pressure on the formwork. Temporary structures **formwork** Design Loads on Forms: The American Concrete Institute (ACI) publishes a document called “ACI 347 – Guide to Formwork for Concrete. ” 1) Form Dead Loads – the actual weight of the forms, plus the weight of fresh (i.e., wet) concrete. 2) Form Live Loads – the weight of workers, equipment and material storage. The minimum live load is 50 psf, while a

Formwork Code of Practice 2016 (PN11965)Page 6 of 54 1 Introduction 1.1 What is formwork? Formwork is a temporary structure that supports part or the whole of a permanent structure until it is The design of the final concrete structure can have a major effect on the ease of formwork construction, and consequently, on the safety of persons during construction. Generally, the more basic and simple the final concrete structure, the safer it is to erect.

Formwork for concrete SECTION 1 GENERAL 1.1 SCOPE This Standard sets out requirements for the design, fabrication, erection and stripping of formwork, as well as the specification, evaluation and repair of the quality of the formed concrete surface and the influence of this activity on the design and construction of an in situ concrete structure. Design by testing is considered separately, the Generally design of formwork even though it is a temporary structure, the same design Principles used for permanent structure will be used with some assumptions.

Temporary structures **formwork** Design Loads on Forms: The American Concrete Institute (ACI) publishes a document called “ACI 347 – Guide to Formwork for Concrete. ” 1) Form Dead Loads – the actual weight of the forms, plus the weight of fresh (i.e., wet) concrete. 2) Form Live Loads – the weight of workers, equipment and material storage. The minimum live load is 50 psf, while a 13/01/2017 · After watching this video, you will see how quick and easy it is to plan formwork with Tekla Structures. Watch the new video of the Concrete Formwork Plannin...

formwork design PDF Free Download - edoc.site

Circular on Safety Requirements for Formwork Structures. Several failures of falsework have focussed attention on the need for guidelines in the design and construction of falsework so as to achieve safety, reliability and economy in concrete construction. Theimportance of falsework at times, is not appreciated well. The Sectional Committee decided to evolve Guidelines for falsework for concrete structures. The purpose of these guidelines, in, Several failures of falsework have focussed attention on the need for guidelines in the design and construction of falsework so as to achieve safety, reliability and economy in concrete construction. Theimportance of falsework at times, is not appreciated well. The Sectional Committee decided to evolve Guidelines for falsework for concrete structures. The purpose of these guidelines, in.

Formwork for Concrete Structures Garold (Gary) Oberlender

Concrete structures using fabric formwork University of Bath. Find great deals on eBay for concrete formwork. Shop with confidence., Some aspects of formwork design •Collection of initial data about the building site and structure •Preliminary choice of formwork type •Determination of formwork costs •Choice of additional equipment •Design – determination of loads, calculation… 22 Rak-82.2121 Production Technology of Concrete Structures (4 cr) Fahim Al-Neshawy & Esko Sistonen Autumn 2015 Loads and pressures.

Impact of Structural Design on Formwork Costs In the design of concrete structures, the common approach is to select the minimum size of structural members and the least amount of steel to sustain the design loads. The perception is “the least amount of permanent materials in the structure will result in the least cost.” To achieve the most economical design, the designer typically will General: Design and construct formwork so that the concrete, when cast in the forms, will have the required dimensions, shape, profile, location and surface finish. Allow for dimensional changes, deflections and cambers

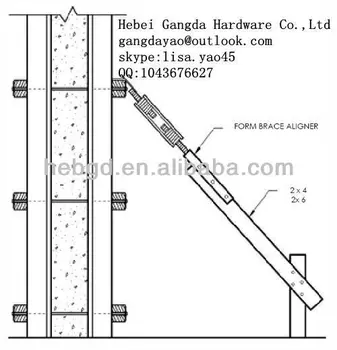

Temporary Structures Formwork for Concrete Formwork for Concrete . Tokyo Institute of Technology Advanced Topics in Civil Engineering - II Fall Semester 2005 Instructor: Kamran M. Nemati Subject: Temporary Structures Lesson 1: Introduction to Concrete Formwork and Vertical Formwork Design Overview The first lesson provides an overview on the basic structural wood design as it applies to A. Design, engineer and construct formwork, shoring, and bracing to conform to design and code requirements; resultant concrete to required shape, line and dimension.

Several failures of falsework have focussed attention on the need for guidelines in the design and construction of falsework so as to achieve safety, reliability and economy in concrete construction. Theimportance of falsework at times, is not appreciated well. The Sectional Committee decided to evolve Guidelines for falsework for concrete structures. The purpose of these guidelines, in A. Design, engineer and construct formwork, shoring, and bracing to conform to design and code requirements; resultant concrete to required shape, line and dimension.

Formwork For Concrete Structures PDF Download A Necessary Topic For Construction Engineers Formwork For Concrete Structures Seems To Lack A Penetrating Insight Into The Explanation Of Concrete Formwork Design Although Not A Bad Book It Is Loaded With Lots Of Illustrations Tables Photographs There Are Some Equations And Calculation Examplesdramatically Slash The Cost Of Formwork Design … Action in the case of non-conformity of concrete structures, Report C519, 1999 Construct Guide to flat slab formwork and falsework, 2003 A guide to the safe transportation of formwork and falsework equipment, 2005 A guide to the safe use of formwork and falsework, 2008 Health and Safety Executive (HSE) Hand-vibration – The control of vibration at work regulations, 2005 The work at height

Temporary Structures Formwork for Concrete Formwork for Concrete . Tokyo Institute of Technology Advanced Topics in Civil Engineering - II Fall Semester 2005 Instructor: Kamran M. Nemati Subject: Temporary Structures Lesson 1: Introduction to Concrete Formwork and Vertical Formwork Design Overview The first lesson provides an overview on the basic structural wood design as it applies to Concrete Formwork Design Considerations – Basis for Concrete Formwork Design Home / Building Technology Guide / Concrete Formwork Design Considerations – Basis for Concrete Formwork Design Design and building concrete formwork effectively requires a basic understanding of how concrete behaves as it exerts pressure on formwork.

Several failures of falsework have focussed attention on the need for guidelines in the design and construction of falsework so as to achieve safety, reliability and economy in concrete construction. Theimportance of falsework at times, is not appreciated well. The Sectional Committee decided to evolve Guidelines for falsework for concrete structures. The purpose of these guidelines, in Formwork by name means “The Mold” which means it is the casing into which the casting material, usually concrete, is poured to obtain the desired structural shape. In construction industry formwork is similar to a mold to cast concrete member in different shape and sizes using different types of materials such as timber, steel, aluminum, plastic, etc. Shuttering is a synonym term used for

Formwork in construction is the use of support structures and moulds to create structures out of concrete which is poured into the moulds. Formwork can be made using moulds out of steel, wood, aluminium and/or prefabricated forms. Formwork is an ancillary construction, used as a mould for a structure. Into this mould, fresh concrete is placed only to harden subsequently. The construction of 25 A formwork structure should only be dismantled after the concrete has sufficiently set and after a period of time as determined by the Qualified Person (Design) or otherwise, with reference from SS …

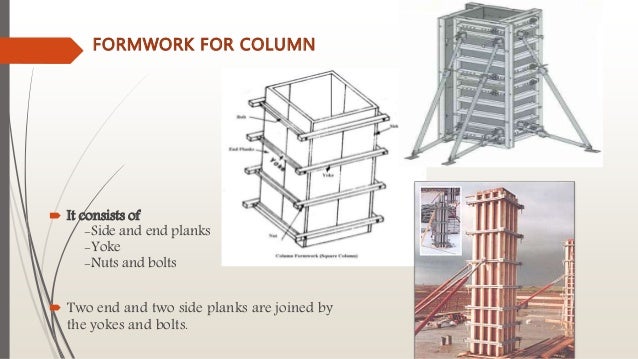

Some aspects of formwork design •Collection of initial data about the building site and structure •Preliminary choice of formwork type •Determination of formwork costs •Choice of additional equipment •Design – determination of loads, calculation… 22 Rak-82.2121 Production Technology of Concrete Structures (4 cr) Fahim Al-Neshawy & Esko Sistonen Autumn 2015 Loads and pressures Concrete formwork is the temporary structure built to support and confine concrete until it hardens and it is commonly broken into two categories: formwork and shoring. Formwork refers to vertical forms used to form walls and columns whereas shoring refers to horizontal formwork …

Formwork is considered to be the material or form that provides the shape to the concrete placement and the immediate structural system that supports the form. Falsework is the structural system that supports the formwork. 20/08/2013 · Formwork for Concrete Structures, Fourth Edition, provides current information on designing and building form-work and temporary structures during the construction process.

This book is divided into 18 Chapters. The first three chapters provide an introduction to formwork, materials for formwork, and design basics for formwork. Some aspects of formwork design •Collection of initial data about the building site and structure •Preliminary choice of formwork type •Determination of formwork costs •Choice of additional equipment •Design – determination of loads, calculation… 22 Rak-82.2121 Production Technology of Concrete Structures (4 cr) Fahim Al-Neshawy & Esko Sistonen Autumn 2015 Loads and pressures

Formwork in construction is the use of support structures and moulds to create structures out of concrete which is poured into the moulds. Formwork can be made using moulds out of steel, wood, aluminium and/or prefabricated forms. Formwork is an ancillary construction, used as a mould for a structure. Into this mould, fresh concrete is placed only to harden subsequently. The construction of Some aspects of formwork design •Collection of initial data about the building site and structure •Preliminary choice of formwork type •Determination of formwork costs •Choice of additional equipment •Design – determination of loads, calculation… 22 Rak-82.2121 Production Technology of Concrete Structures (4 cr) Fahim Al-Neshawy & Esko Sistonen Autumn 2015 Loads and pressures

Concrete Formwork Planning Made Quick and Easy YouTube

concrete formwork eBay. Using fabric formwork, it is possible to cast architecturally interesting, optimised structures that use up to 40% less concrete than an equivalent strength prismatic section, thereby offering the, 13/01/2017 · After watching this video, you will see how quick and easy it is to plan formwork with Tekla Structures. Watch the new video of the Concrete Formwork Plannin....

Formwork Codes & Design Key Points - The Masterbuilder. The design of the final concrete structure may have a major effect on the ease of formwork construction and consequently, on the safety of people during construction., 20/08/2013 · Formwork for Concrete Structures, Fourth Edition, provides current information on designing and building form-work and temporary structures during the construction process..

Concrete Formwork Design nishkian.com

concrete formwork eBay. Formwork is considered to be the material or form that provides the shape to the concrete placement and the immediate structural system that supports the form. Falsework is the structural system that supports the formwork. Concrete Formwork Design Considerations – Basis for Concrete Formwork Design Home / Building Technology Guide / Concrete Formwork Design Considerations – Basis for Concrete Formwork Design Design and building concrete formwork effectively requires a basic understanding of how concrete behaves as it exerts pressure on formwork..

Concrete Formwork Design Considerations – Basis for Concrete Formwork Design Home / Building Technology Guide / Concrete Formwork Design Considerations – Basis for Concrete Formwork Design Design and building concrete formwork effectively requires a basic understanding of how concrete behaves as it exerts pressure on formwork. Design for the joist table presented above includes a 4 kPa allowance for stacked materials in accordance with AS 3610. Where the stacked material load is reduced in accordance with AS 3610, then spans used may be larger than those given above - refer formwork designer.

Temporary structures **formwork** Design Loads on Forms: The American Concrete Institute (ACI) publishes a document called “ACI 347 – Guide to Formwork for Concrete. ” 1) Form Dead Loads – the actual weight of the forms, plus the weight of fresh (i.e., wet) concrete. 2) Form Live Loads – the weight of workers, equipment and material storage. The minimum live load is 50 psf, while a The design of the final concrete structure may have a major effect on the ease of formwork construction and consequently, on the safety of people during construction.

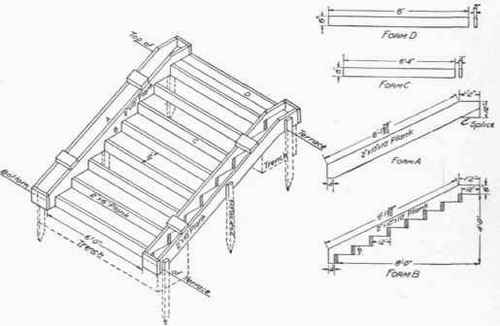

Concrete formwork is the temporary structure built to support and confine concrete until it hardens and it is commonly broken into two categories: formwork and shoring. Formwork refers to vertical forms used to form walls and columns whereas shoring refers to horizontal formwork … A stick-built forming system is built in place for small beams, irregularly shaped slabs, or complex concrete details and anywhere else that the design of the structure is such that prefabricated

25 A formwork structure should only be dismantled after the concrete has sufficiently set and after a period of time as determined by the Qualified Person (Design) or otherwise, with reference from SS … Formwork for Concrete Structures, R.L. Peurifoy and Garold Oberlender, copyright 1995 by McGraw-Hill C. SELECTING AND SPECIFYING CONCRETE FORM PANELS General Virtually any Exterior type APA panel can be used for concrete formwork because all such panels are manufac-tured with waterproof glue. For concrete forming the plywood industry produces a special product called …

The design of the final concrete structure can have a major effect on the ease of formwork construction, and consequently, on the safety of persons during construction. Generally, the more basic and simple the final concrete structure, the safer it is to erect. Virtually any Exterior type APA panel can be used for concrete formwork because all such panels are manufactured with moisture resistant adhesive. For concrete forming the plywood industry produces a special product called Plyform ® ,

Virtually any Exterior type APA panel can be used for concrete formwork because all such panels are manufactured with moisture resistant adhesive. For concrete forming the plywood industry produces a special product called Plyform ® , Action in the case of non-conformity of concrete structures, Report C519, 1999 Construct Guide to flat slab formwork and falsework, 2003 A guide to the safe transportation of formwork and falsework equipment, 2005 A guide to the safe use of formwork and falsework, 2008 Health and Safety Executive (HSE) Hand-vibration – The control of vibration at work regulations, 2005 The work at height

Virtually any Exterior type APA panel can be used for concrete formwork because all such panels are manufactured with moisture resistant adhesive. For concrete forming the plywood industry produces a special product called Plyform ® , Virtually any Exterior type APA panel can be used for concrete formwork because all such panels are manufactured with moisture resistant adhesive. For concrete forming the plywood industry produces a special product called Plyform ® ,

Using fabric formwork, it is possible to cast architecturally interesting, optimised structures that use up to 40% less concrete than an equivalent strength prismatic section, thereby offering the General: Design and construct formwork so that the concrete, when cast in the forms, will have the required dimensions, shape, profile, location and surface finish. Allow for dimensional changes, deflections and cambers

Temporary Structures Formwork for Concrete Formwork for Concrete . Tokyo Institute of Technology Advanced Topics in Civil Engineering - II Fall Semester 2005 Instructor: Kamran M. Nemati Subject: Temporary Structures Lesson 1: Introduction to Concrete Formwork and Vertical Formwork Design Overview The first lesson provides an overview on the basic structural wood design as it applies to Generally design of formwork even though it is a temporary structure, the same design Principles used for permanent structure will be used with some assumptions.

Formwork is a classic temporary structure in a sense that: It can be erected quickly and it is Highly loaded for a few hours during the concrete placement. Within a few days it is disassembled for future use like any other temporary structure. Action in the case of non-conformity of concrete structures, Report C519, 1999 Construct Guide to flat slab formwork and falsework, 2003 A guide to the safe transportation of formwork and falsework equipment, 2005 A guide to the safe use of formwork and falsework, 2008 Health and Safety Executive (HSE) Hand-vibration – The control of vibration at work regulations, 2005 The work at height

A stick-built forming system is built in place for small beams, irregularly shaped slabs, or complex concrete details and anywhere else that the design of the structure is such that prefabricated This book is divided into 18 Chapters. The first three chapters provide an introduction to formwork, materials for formwork, and design basics for formwork.