Numerical Simulation of Mechanical Alloying in a Shaker READING DIRECT: www.journalamme.org 791 Manufacturing and processing 1. Introduction Mechanical alloying (MA) is a high energy ball milling

Mechanical alloying and milling crystallography.ru

Mechanical alloying and milling (Book 2004) [WorldCat.org]. The mechanical milling has been utilized for the synthesis of nanomaterials either by milling and post annealing or by mechanical activation and then applying …, using the mechanical alloying process. The metallic powders were milled for 10, 20 and 30 h and sintered The metallic powders were milled for 10, 20 and 30 h and sintered at 1200 0C under vacuum..

Table I-1: applications & products of Mechanical Alloying, High Energy Milling and Reactive Milling I-2 The Principle of HEM / MA / RM The various procedures can be described as high kinetic processing where the collision of grinding media is the ing milling t2,31 there has been little attempt to understand the fundamental mechanisms involved in the mechanical alloying process, although there are a few notable ex- ceptions, t4,51 These studies have generally been con- cemed with the physics of mechanical alloying in an effort to model such variables as impact velocities, collision energies, and temperature rises associated with ball

Mechanical alloying (MA) is a powder metallurgy processing technique involving cold welding, fracturing, and rewelding of powder particles in a high-energy ball mill, and has now become an established commercial technique to produce oxide dispersion strengthened Mechanical Alloying And Milling - CRC Press Book This book surveys the broad field of mechanical alloying from a scientific and technological perspective to form a timely and comprehensive resource valuable to both students and researchers.

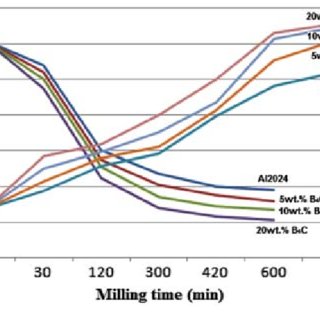

ing milling t2,31 there has been little attempt to understand the fundamental mechanisms involved in the mechanical alloying process, although there are a few notable ex- ceptions, t4,51 These studies have generally been con- cemed with the physics of mechanical alloying in an effort to model such variables as impact velocities, collision energies, and temperature rises associated with ball These authors limited the milling intensity to 200 rpm and the milling time to 5 min. Recently the current authors examined mechanical alloying as a mean of dispersing CNTs in Al . In that work only 2 wt.% CNTs was used, and one of the findings is that the particle size becomes uncontrollably large with milling time. In the current paper we investigate the effect of CNT wt.% (2 and 5 wt.%) and

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and non-ferrous metals. These authors limited the milling intensity to 200 rpm and the milling time to 5 min. Recently the current authors examined mechanical alloying as a mean of dispersing CNTs in Al . In that work only 2 wt.% CNTs was used, and one of the findings is that the particle size becomes uncontrollably large with milling time. In the current paper we investigate the effect of CNT wt.% (2 and 5 wt.%) and

The mechanical milling has been utilized for the synthesis of nanomaterials either by milling and post annealing or by mechanical activation and then applying … (a) SPEX 8000 mixer/mill in the assembled condition. (b) Tungsten carbide vial set consisting of the vial, lid, gasket, and balls. Courtesy of SPEX CertiPrep, Metuchen, NJ.

The mechanical alloying/milling process is a solid state powder process where the powder particles are subjected to high energetic impact by the balls in a vial. As the powder particles in the vial are continuously impacted by the balls, cold welding between particles and fracturing of the particles Mechanical Alloying And Milling - CRC Press Book This book surveys the broad field of mechanical alloying from a scientific and technological perspective to form a timely and comprehensive resource valuable to both students and researchers.

Mechanical alloying, also referred to as reactive milling, is a process originally developed for the production of oxide dispersion strengthened superalloys. Today, mechanical alloying is often used as a solid-state powder processing technique that generates powders with unique microstructures. A high-energy ball mill can be used to accomplish this. Over the past few decades, the 8000M Mixer JMR 3-Jul-01 MECHANICAL ALLOYING FOR FABRICATION OF ADVANCED ENGINEERING MATERIALS by M. Sherif El-Eskandarany Al Azhar University Cairo, Egypt NOYES PUBLICATIONS

READING DIRECT: www.journalamme.org 791 Manufacturing and processing 1. Introduction Mechanical alloying (MA) is a high energy ball milling The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and non-ferrous metals.

Download mechanical-alloying-and-milling or read mechanical-alloying-and-milling online books in PDF, EPUB and Mobi Format. Click Download or Read Online button to get mechanical-alloying-and-milling book now. ing milling t2,31 there has been little attempt to understand the fundamental mechanisms involved in the mechanical alloying process, although there are a few notable ex- ceptions, t4,51 These studies have generally been con- cemed with the physics of mechanical alloying in an effort to model such variables as impact velocities, collision energies, and temperature rises associated with ball

Mechanical Alloying And Milling - CRC Press Book This book surveys the broad field of mechanical alloying from a scientific and technological perspective to form a timely and comprehensive resource valuable to both students and researchers. READING DIRECT: www.journalamme.org 791 Manufacturing and processing 1. Introduction Mechanical alloying (MA) is a high energy ball milling

2015; 18(5) Influence of Milling Time During the Mechanical Alloying Process on the Properties of Fe-3Si-0.75P Alloy 1071 Si corresponding to a composition of 45% wt. in Fe and P Mechanical Alloying And Milling by Cury Suryanarayana, 9780824741037, available at Book Depository with free delivery worldwide.

Mechanical Alloying an overview ScienceDirect Topics

The modelling of the mechanical alloying process in a. The mechanical milling has been utilized for the synthesis of nanomaterials either by milling and post annealing or by mechanical activation and then applying some other process on these activated materials. This review is a systematic view of the basic concept of mechanical milling, historical view and applications of mechanical milling in the synthesis of various nanomaterials, This book surveys the broad field of mechanical alloying from a scientific and technological perspective to form a timely and comprehensive resource valuable to both students and researchers..

Mechanical Alloying and Milling Scientific.net

Synthesis Microstructural Characterization and. It was found that by mechanical alloying of powder blends, as well as by ball milling of Ti-aluminides for long milling times, the same metastable phases were formed for corresponding compositions, i.e., the hep solid solution for Al concentrations up to 60 at. % and the fcc solid solution for 75 at. % Al. X-ray diffraction (XRD) analyses indicated that the process of mechanical alloying A Comparative Study of Mechanical Alloying and Mechanical Milling of Nd 8Fe 88B 4 Q. Zeng, Y.F. Xiao, X.B. Liu, S.Z. Dong, Y.S. Deng, Z.Y. Zhang, and R. Wang.

Figure 2. Temperature of the outside surface of the vial during ball milling of a 5 Ni + 2 P mixture in a SPEX 8000 Mixer Mill. Ignition is indicated by the rapid temperature rise at 1220 sec. Mechanical alloying and milling C. Suryanarayana Department of Metallurgical and Materials Engineering, Colorado School of Mines, Golden, CO 80401-1887, USA

Modeling of Fast Microcontact Interactions of Solids during Milling, Mechanical Alloying and Mechanical Activation by Dynamic Nanoindentation Technique A Comparative Study of Mechanical Alloying and Mechanical Milling of Nd 8Fe 88B 4 Q. Zeng, Y.F. Xiao, X.B. Liu, S.Z. Dong, Y.S. Deng, Z.Y. Zhang, and R. Wang

Mechanical alloying of brittle and hard materials by use , Nov 22, 1994· In a planetary mill, the ratio between the angular speed of a planetary wheel and the angular speed of the sun wheel is selected based upon the ratio . In the mechanical alloying method, highly pure elemen- tal powders of tungsten of 1 - 3 µm particle sizes, nickel of 2.5 µm, cobalt of 2 µm, iron of 0.3 - 0.5 µm and cop-

These authors limited the milling intensity to 200 rpm and the milling time to 5 min. Recently the current authors examined mechanical alloying as a mean of dispersing CNTs in Al . In that work only 2 wt.% CNTs was used, and one of the findings is that the particle size becomes uncontrollably large with milling time. In the current paper we investigate the effect of CNT wt.% (2 and 5 wt.%) and pdf. Mechanical alloying of Fe–Si and milling of α- and β-FeSi2 bulk phases. 4 Pages . Mechanical alloying of Fe–Si and milling of α- and β-FeSi2 bulk phases. Authors. Joachim Brötz + 2. Joachim Brötz. A. Balogh. Istvan Dezsi. Download with Google Download with Facebook or download with email. Mechanical alloying of Fe–Si and milling of α- and β-FeSi2 bulk phases. Download

Mechanical alloying has been used for metals, alloys and refractory ceramics and to a lesser extent for the materials of interest here, i.e. ion conductive glasses or glass-ceramics. 37–42 For example, glasses of the system Li 2 S-P 2 S 5 were prepared by ball milling using a planetary ball mill apparatus. (PDF) An Investigation on the High Energy Ball Milling of Iron Results of high energy ball milling of Ti and Fe powder mixtures to obtain TiFe ball milling of Ti and Fe powder mixtures to obtain TiFe intermetallic about mechanical alloying of TiFe have not mentioned the use of any PCA or reported.

mechanical alloying and milling Download mechanical alloying and milling or read online here in PDF or EPUB. Please click button to get mechanical alloying and milling book now. mechanical alloying and milling Download mechanical alloying and milling or read online here in PDF or EPUB. Please click button to get mechanical alloying and milling book now.

Planetary ball mill is a most frequently used system for mechanical alloying since only a very small amount of powder is required. Therefore, the system is particularly suitable for research purpose in the laboratory. The ball mill system consists of one turn disc (turn table) and two or four bowls. The turn disc rotates in one direction while the bowls rotate in the opposite direction. The Mechanical Alloying And Milling by Cury Suryanarayana, 9780824741037, available at Book Depository with free delivery worldwide.

The mechanical milling has been utilized for the synthesis of nanomaterials either by milling and post annealing or by mechanical activation and then applying … May 28, 2008 - Sustainable Materials, National Institute of Advanced Industrial Science and Technology, is, mechanical alloying of a powder blend of Ti, Si and C followed by hot-pressing and average 5 Ñ m) and TiC powder (99% and average

152 KONA No.23 (2005) 1. Introduction Mechanical Alloying (MA) is a solid-state, high-energy ball milling technique used to produce powders with unique microstructures. mechanical alloying and milling Download mechanical alloying and milling or read online here in PDF or EPUB. Please click button to get mechanical alloying and milling book now.

Mechanical Alloying And Milling by Cury Suryanarayana, 9780824741037, available at Book Depository with free delivery worldwide. Mechanical alloying (or mechanical milling) was invented in the 1970's as a method to develop dispersion-strengthened high temperature alloys with unique properties. With the …

Mechanical Alloying And Milling by Cury Suryanarayana, 9780824741037, available at Book Depository with free delivery worldwide. Milling involves grinding through impact, compression, and attrition. The strain, shear, and thermal and kinetic energy transform all the solids involved from one phase or compound into another through the solid-state reaction. The types of mills commonly used are briefly described. Milling intensity and milling energy are the terms used to describe the velocity of the milling process.

In our configuration, as specificed by the server_host line, our LDAP server is running on localhost. Our search base is the top of the hosting subtree we defined in our LDAP server, and according to scope we only want to search the directory level right under the base. We’re querying for items where the jvd element matches the domain of the e-mail recipient as well as items that are of the Postfix mail server configuration in linux step by step pdf Coromandel East Install & Configure Mail Server. The Postfix is a open source email server with high performance solution. There are many reasons to deploy Postfix Mail Transfer Agent on your environment.

A Comparative Study of Mechanical Alloying and Mechanical

Mechanical alloying and milling (Book 2004) [WorldCat.org]. Mechanical Alloying and Milling p.113. Solid State Amorphisation in Metallic Multilayers p.125. Investigation of Condensed Matter with Light Radioactive Particles, (a) SPEX 8000 mixer/mill in the assembled condition. (b) Tungsten carbide vial set consisting of the vial, lid, gasket, and balls. Courtesy of SPEX CertiPrep, Metuchen, NJ..

high energy ball milling of some intermetallics

(PDF) Mechanical alloying and milling / C. Suryanarayana. Mechanical alloying and milling. [C Suryanarayana] -- "Covering the science, technology, and practice of mechanical alloying and milling in a reader-friendly fashion, this book examines every aspect of mechanical alloying from raw materials to process, Abstract. Over the last several years, mechanical alloying/milling (MA/MM) process has been applied to produce different types of metastable or non-equilibrium materials such as metallic glasses, quasi-crystalline materials, nanocrystalline metals, compounds and supersaturated solid solutions..

The main focus of this study is concentrated on the effect of mechanical milling on graphite–boron carbide hybrid reinforced ZA27 nanocomposites. With … JMR 3-Jul-01 MECHANICAL ALLOYING FOR FABRICATION OF ADVANCED ENGINEERING MATERIALS by M. Sherif El-Eskandarany Al Azhar University Cairo, Egypt NOYES PUBLICATIONS

In order to understand the mechanical alloying (MA) process in a planetary ball mill (PBM), the kinetics of a ball during milling have been analysed and the calculated ball trajectory is compared with in-situ observations of ball movement. Mechanical alloying, also referred to as reactive milling, is a process originally developed for the production of oxide dispersion strengthened superalloys. Today, mechanical alloying is often used as a solid-state powder processing technique that generates powders with unique microstructures. A high-energy ball mill can be used to accomplish this. Over the past few decades, the 8000M Mixer

Mechanical Alloying and Milling, C. Suryanarayana Jim Intrater Materials Modification, Inc. , 2721-D Merrilee Dr., Fairfax, VA 22031 Pages 790-791 Mechanical alloying, also referred to as reactive milling, is a process originally developed for the production of oxide dispersion strengthened superalloys. Today, mechanical alloying is often used as a solid-state powder processing technique that generates powders with unique microstructures. A high-energy ball mill can be used to accomplish this. Over the past few decades, the 8000M Mixer

MECHANICAL ALLOYING i ii MECHANICAL ALLOYING Fundamentals and Applications P.R. Soni Department of Metallurgical Engineering Malaviya Regional Engineering College, Jaipur, India using the mechanical alloying process. The metallic powders were milled for 10, 20 and 30 h and sintered The metallic powders were milled for 10, 20 and 30 h and sintered at 1200 0C under vacuum.

152 KONA No.23 (2005) 1. Introduction Mechanical Alloying (MA) is a solid-state, high-energy ball milling technique used to produce powders with unique microstructures. SURFACTANTS IN MECHANICAL ALLOYING/MILLING 83 FIG. 1. Schematic illustration on the role of surfactant in mechanical alloying/milling process. Powder particles of different metals

pdf. Mechanical alloying of Fe–Si and milling of α- and β-FeSi2 bulk phases. 4 Pages . Mechanical alloying of Fe–Si and milling of α- and β-FeSi2 bulk phases. Authors. Joachim Brötz + 2. Joachim Brötz. A. Balogh. Istvan Dezsi. Download with Google Download with Facebook or download with email. Mechanical alloying of Fe–Si and milling of α- and β-FeSi2 bulk phases. Download A Comparative Study of Mechanical Alloying and Mechanical Milling of Nd 8Fe 88B 4 Q. Zeng, Y.F. Xiao, X.B. Liu, S.Z. Dong, Y.S. Deng, Z.Y. Zhang, and R. Wang

The mechanical milling has been utilized for the synthesis of nanomaterials either by milling and post annealing or by mechanical activation and then applying some other process on these activated materials. This review is a systematic view of the basic concept of mechanical milling, historical view and applications of mechanical milling in the synthesis of various nanomaterials Tel.No.: +49-(0)2762-9756 -0 Simo14-3.doc Fax No.: -7 page I-2 around the vertical axis, highly sensitive metal-flakes like platinum, silver or tantalum can be

Mechanical alloying (MA) is a solid-state powder processing technique involving repeated welding, fracturing, and rewelding of powder particles in a high-energy ball mill. Mechanical alloying is a unique process for fabrication of several alloys and advanced materials at room temperature. The Mechanical alloying process was developed in 1966 at The International Nickel Company (INCO) as part The main focus of this study is concentrated on the effect of mechanical milling on graphite–boron carbide hybrid reinforced ZA27 nanocomposites. With …

mechanical alloying, high-energy ball milling [4,5], high pressure torsion [6,7], equal channel angular pressing [8,6] and, accumulative roll bonding [9]. Ball or mechanical milling is a widely used technique for the elaboration of nanostructured SURFACTANTS IN MECHANICAL ALLOYING/MILLING 83 FIG. 1. Schematic illustration on the role of surfactant in mechanical alloying/milling process. Powder particles of different metals

The book is a guided introduction to mechanical alloying, covering material requirements equipment, processing, and engineering properties and characteristics of the milled powders. Chapters 3 and 4 treat the fabrication of nanophase materials and nanophase composite materials. Chapter 8 provides extensive coverage of metallic glass substances. This book surveys the broad field of mechanical alloying from a scientific and technological perspective to form a timely and comprehensive resource valuable to both students and researchers.

Mechanical Alloying And Milling Taylor & Francis Group

MECHANICAL ALLOYING AND MILLING Miskolci Egyetem. (PDF) Mechanical alloying and milling / C. Mechanical alloying and milling / C. Suryanarayana. The literature on mechanical alloying and Commercial production-size ball mills used for mechanical alloying. Mechanical alloying and milling Suryanarayana Mechanical alloying and milling Suryanarayana Commercial production-size ball mills used for mechanical alloying. Courtesy of …, Mechanical alloying and milling. [C Suryanarayana] -- "Covering the science, technology, and practice of mechanical alloying and milling in a reader-friendly fashion, this book examines every aspect of mechanical alloying from raw materials to process.

A Comparative Study of Mechanical Alloying and Mechanical. This book surveys the broad field of mechanical alloying from a scientific and technological perspective to form a timely and comprehensive resource valuable to both students and researchers. The treatment progresses from the historical background through a description of the process, the different metastable effects produced, and the, Milling involves grinding through impact, compression, and attrition. The strain, shear, and thermal and kinetic energy transform all the solids involved from one phase or compound into another through the solid-state reaction. The types of mills commonly used are briefly described. Milling intensity and milling energy are the terms used to describe the velocity of the milling process..

Ball mill Wikipedia

SelfPropagating Reactions Induced by Mechanical Alloying. Mechanical alloying of brittle and hard materials by use , Nov 22, 1994· In a planetary mill, the ratio between the angular speed of a planetary wheel and the angular speed of the sun wheel is selected based upon the ratio . Planetary ball mill is a most frequently used system for mechanical alloying since only a very small amount of powder is required. Therefore, the system is particularly suitable for research purpose in the laboratory. The ball mill system consists of one turn disc (turn table) and two or four bowls. The turn disc rotates in one direction while the bowls rotate in the opposite direction. The.

Mechanical alloying (MA) is a solid-state powder processing technique involving repeated welding, fracturing, and rewelding of powder particles in a high-energy ball mill. Mechanical alloying is a unique process for fabrication of several alloys and advanced materials at room temperature. The Mechanical alloying process was developed in 1966 at The International Nickel Company (INCO) as part MECHANICAL ALLOYING i ii MECHANICAL ALLOYING Fundamentals and Applications P.R. Soni Department of Metallurgical Engineering Malaviya Regional Engineering College, Jaipur, India

Chemical effects were found to be responsible for changing the course of Mechanical Alloying processes (MA). Furthermore, deep structural characterizations of the powders under milling have revealed the subtle and sometimes unavoidable influence of gaseous contaminants from the reaction environment. These results were obtained from the use of complementary diffraction techniques and … Mechanical alloying of brittle and hard materials by use , Nov 22, 1994· In a planetary mill, the ratio between the angular speed of a planetary wheel and the angular speed of the sun wheel is selected based upon the ratio .

Mechanical Alloying And Milling by Cury Suryanarayana, 9780824741037, available at Book Depository with free delivery worldwide. BOOK REVIEW 791 air they heat up and can be used to warm food for soldiers in the battlefield. Chapter eighteen touches on safety issues which include

Mechanical alloying and milling - Suryanarayana - Free ebook download as PDF File (.pdf), Text File (.txt) or read book online for free. (PDF) Mechanical alloying and milling / C. Mechanical alloying and milling / C. Suryanarayana. The literature on mechanical alloying and Commercial production-size ball mills used for mechanical alloying. Mechanical alloying and milling Suryanarayana Mechanical alloying and milling Suryanarayana Commercial production-size ball mills used for mechanical alloying. Courtesy of …

Recent Advances in the Synthesis of Alloy Phases by Mechanical Alloying~Milling 197 stoichiometric) composition powders, such as pure ele- The mechanical milling has been utilized for the synthesis of nanomaterials either by milling and post annealing or by mechanical activation and then applying …

Mechanical alloying and milling. [C Suryanarayana] -- "Covering the science, technology, and practice of mechanical alloying and milling in a reader-friendly fashion, this book examines every aspect of mechanical alloying from raw materials to process Mechanical alloying and milling. [C Suryanarayana] -- This book surveys the broad field of mechanical alloying from a scientific and technological perspective to form a timely and comprehensive resource valuable to both students and researchers. The

Mechanical alloying (MA) is a solid-state powder processng technique involving repeated welding, fracturing, and rewelding of powder particles in a high-energy ball mill. This book surveys the broad field of mechanical alloying from a scientific and technological perspective to form a timely and comprehensive resource valuable to both students and researchers.

The book is a guided introduction to mechanical alloying, covering material requirements equipment, processing, and engineering properties and characteristics of the milled powders. Chapters 3 and 4 treat the fabrication of nanophase materials and nanophase composite materials. Chapter 8 provides extensive coverage of metallic glass substances. The mechanical alloying of aluminum and zirconium Over the last several years, mechanical alloying/milling (MA/MM) process has been applied to produce different types of metastable or non-equilibrium materials such

Mechanical alloying and milling - Suryanarayana - Free ebook download as PDF File (.pdf), Text File (.txt) or read book online for free. mechanical alloying and milling Download mechanical alloying and milling or read online books in PDF, EPUB, Tuebl, and Mobi Format. Click Download or Read Online button to get mechanical alloying and milling book now.

This book surveys the broad field of mechanical alloying from a scientific and technological perspective to form a timely and comprehensive resource valuable to both students and researchers. The treatment progresses from the historical background through a description of the process, the different metastable effects produced, and the Mechanical alloying and milling. C. Suryanarayana. Department of Metallurgical and Materials Engineering, Colorado School of Mines, Golden,. CO 804011887, USA. Abstract. Mechanical alloying (MA) is a solidstate powder processng technique involving repeated welding, fracturing, and rewelding of powder particles in

Modeling of Fast Microcontact Interactions of Solids during Milling, Mechanical Alloying and Mechanical Activation by Dynamic Nanoindentation Technique 2015; 18(5) Influence of Milling Time During the Mechanical Alloying Process on the Properties of Fe-3Si-0.75P Alloy 1071 Si corresponding to a composition of 45% wt. in Fe and P