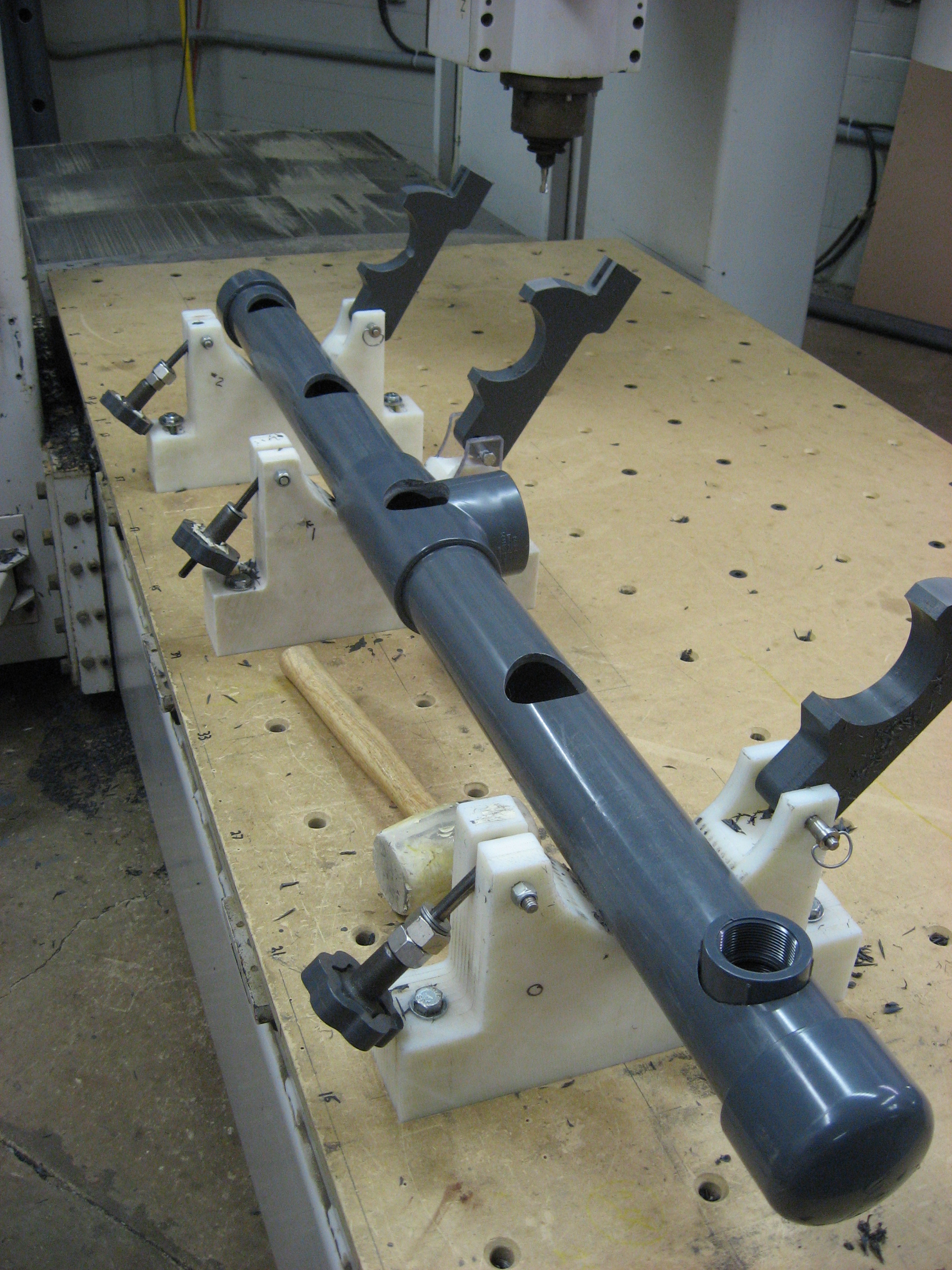

PPT – Intake and Exhaust Manifold Design Part 1 In this paper a new manufacturing process for fabricating intake manifolds for Formula SAE race cars is presented. Specifically, an intake manifold system is fabricated in a two-step process…

Berklee Exhaust Systems and Manufacturing Solutions

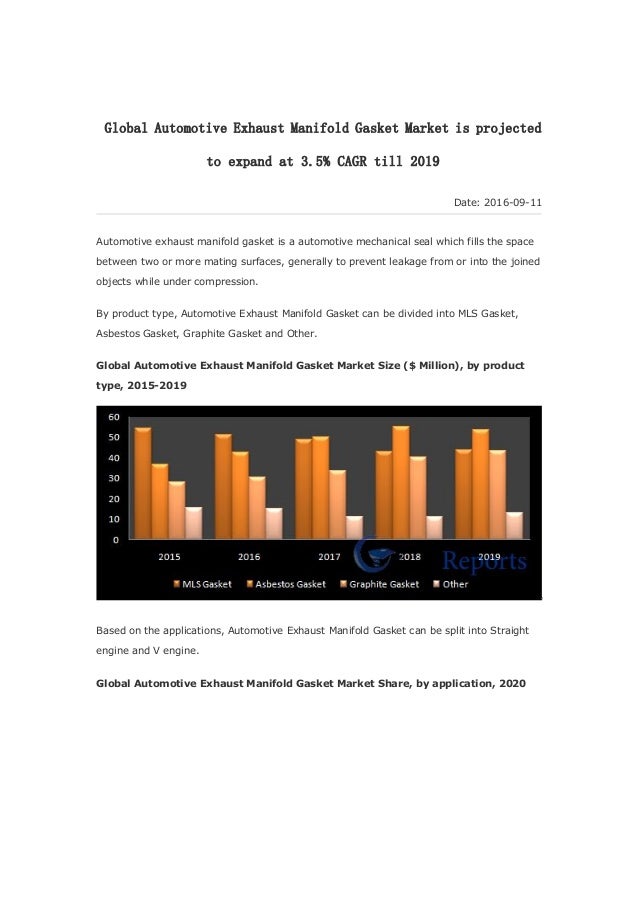

Stainless steel manifold All industrial manufacturers. A process is provided for manufacturing an exhaust manifold. The manifold comprises at least one stamp formed inlet flange, a stamp formed sheet metal inner shell and a …, In the Global Automotive Exhaust Manifold Gasket Industry Market Analysis & Forecast 2018-2023, the revenue is valued at USD XX million in 2017 and is expected to reach USD XX million by the end of 2023, growing at a CAGR of XX% between 2018 and 2023. The production is ….

The manifold extends from the cylinders to the exhaust pipe, collecting and moving exhaust away from the engine. Exhaust can be harmful to inhale, making it very important to have a fully functional exhaust manifold. The manifold consists of a series of pipes which connects to the cylinders and then consolidate in a central large pipe which vents to the exhaust pipe. About Us Our factory has manifold and exhaust manifold, the diameter of exhaust manifold, and the location of the switching valve. The diameter of the branch exhaust manifold is usually the

Second-Generation Catalytic Converter – the Dual-Bed System. Carmakers and Catalyst Companies Were Working on the Second-Generation Catalytic Converter – the Dual-Bed System. Air 2% O 2 Air Pump Exhaust Manifold Engine: Air/Fuel Calibration 13.5 to 14.5 NO Reduction Catalyst Oxidation Catalyst HC + CO OXIDATION AND NOx REDUCTION BY EXHAUST CATALYST REQUIRED … High-quality Ductile Iron Clay Sand Castings Exhaust Manifold for Agricultural Machinery, find complete details about High-quality Ductile Iron Clay Sand Castings Exhaust Manifold for Agricultural Machinery, ductile iron castings, Exhaust manifold, Agricultural Machinery parts - New Densen Co., Ltd.

Sourcing Guide for Exhaust: China manufacturing industries are full of strong and consistent exporters. We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: spare parts, auto parts, muffler. Exhaust Manifold Design – FEA Approach Gopaal#1, in the design process of the exhaust manifold. The paper focuses on the application of constitutive equation to the thermo mechanical condition of a model based on isothermal data. Using the proposed model, the thermal stress analysis and life prediction of exhaust manifold made of 429EM stainless steel is done. A.K.M. Mohiuddin, …

China Cast Iron Exhaust Manifold for Auto, Find details about China Manifold, Exhaust Manifold from Cast Iron Exhaust Manifold for Auto - Qingdao Seger Industrial Co., Ltd. manifold and exhaust manifold, the diameter of exhaust manifold, and the location of the switching valve. The diameter of the branch exhaust manifold is usually the

second case, the pipe radius of the entire exhaust manifold is considered as a design variable because the pipe radius is known important for the performance of the exhaust manifold … The suitable produciton process for cast iron manifolds is molding machine and shell molding . Molding machine is good for making the outside moulds, and shell molding process is good for making the inside sand cores. The perfect assembly could produce qualified ductile iron and gray iron manifolds.

Jiajun Auto Accessories Manufacturing Co. Ltd..pdf Jiajun Auto Accessories Manufacturing Co. Ltd. Our product catalog is for automobile exhaust systems and auto parts. Jiajun Auto Accessories Manufacturing Co. Ltd..pdf Jiajun Auto Accessories Manufacturing Co. Ltd. Our product catalog is for automobile exhaust systems and auto parts.

EXHAUST MANIFOLD TYPES AND MATERIALS Exhaust manifolds are classified as cast and fabricated. is depicted in Figure 2. thermal expansion coefficient difference) in combination with the structure geometry (stiffness distribution) To highlight. which could be infeasible in an engine development timeframe. 90-806535970 1296 MECHANICAL INFORMATION - 3A-1 Engine Identification 4 Cylinder 73584 a a - Location of G.M. Engine Code MCM (Stern Drive) Code Rotation

tasked with researching, designing, and manufacturing header and muffler components with engine it is necessary to understand the combustion process. The four unique processes in an ignition cycle of a 4Вstroke engine are intake, compression, power, and exhaust. Figure 1 demonstrates the combustion cycle as (1) cylinder expansion for intake of air and fuel; (2) cylinder compression for Second-Generation Catalytic Converter – the Dual-Bed System. Carmakers and Catalyst Companies Were Working on the Second-Generation Catalytic Converter – the Dual-Bed System. Air 2% O 2 Air Pump Exhaust Manifold Engine: Air/Fuel Calibration 13.5 to 14.5 NO Reduction Catalyst Oxidation Catalyst HC + CO OXIDATION AND NOx REDUCTION BY EXHAUST CATALYST REQUIRED …

design constraints for cast-iron manifolds create internal air resistance making it difficult for exhaust gas to flow freely as it exits a cylinder, which robs the engine of horsepower. Jiajun Auto Accessories Manufacturing Co. Ltd..pdf Jiajun Auto Accessories Manufacturing Co. Ltd. Our product catalog is for automobile exhaust systems and auto parts.

China Cast Iron Exhaust Manifold for Auto, Find details about China Manifold, Exhaust Manifold from Cast Iron Exhaust Manifold for Auto - Qingdao Seger Industrial Co., Ltd. This assignment looks into the material selection and manufacturing process for an automotive exhaust system considering the operational requirements. Towards the end, the application of alternate material is also discussed. Working Requirements The maximum temperature in an automobile exhaust

Variable geometry exhaust manifold turbocharging system

US6604358B2 Exhaust manifold - Google Patents. In this paper a new manufacturing process for fabricating intake manifolds for Formula SAE race cars is presented. Specifically, an intake manifold system is fabricated in a two-step process…, Jiajun Auto Accessories Manufacturing Co. Ltd..pdf Jiajun Auto Accessories Manufacturing Co. Ltd. Our product catalog is for automobile exhaust systems and auto parts..

Global Automotive Exhaust Manifold Gasket Industry Market. Manufacturing workflows rely on the communication of clear data between all involved in design and production. PDF3D understands how important collaboration is to professionals working in aerospace and manufacturing, and has taken 3D PDF publishing and conversion …, manifold and exhaust manifold, the diameter of exhaust manifold, and the location of the switching valve. The diameter of the branch exhaust manifold is usually the.

Global Automotive Exhaust Manifold Gasket Industry Market

Berklee Exhaust Systems and Manufacturing Solutions. Jiajun Auto Accessories Manufacturing Co. Ltd..pdf Jiajun Auto Accessories Manufacturing Co. Ltd. Our product catalog is for automobile exhaust systems and auto parts. This report studies the global Automotive Exhaust Manifold Gasket market status and forecast, categorizes the global Automotive Exhaust Manifold Gasket market size (value & volume) by manufacturers, type, application, and region..

COMBINED CYCLE JOURNAL, Second Quarter 2008 3 E O side of the expansion joint. Next, the upstream exhaust manifold flange is unbolted from the exhaust cylinder. The Cadic Corporation has established a mass production facility to produce near net shape stainless steel exhaust manifolds using Cadic's patented Convert Mold Process. The Cadic process converts ordinary mass-produced organic bonded sand molds into …

tasked with researching, designing, and manufacturing header and muffler components with engine it is necessary to understand the combustion process. The four unique processes in an ignition cycle of a 4Вstroke engine are intake, compression, power, and exhaust. Figure 1 demonstrates the combustion cycle as (1) cylinder expansion for intake of air and fuel; (2) cylinder compression for Overview A new market study, titled "Global Automotive Exhaust Manifold Gasket Industry Market Analysis & Forecast 2018-2023 by Manufacturers, Regions, Type and Application, Forecast to 2023" has been featured on amplemarketreports.com.

The process uses a precision mandrel positioned inside the tube during the bending process. This end result is a smooth, aesthetically pleasing appearance as it maintains the full inside tube diameter throughout the bend area. The use of mandrel bend pipes aids in reducing exhaust … IMPORTANT SAFETY RECALL R57 / NHTSA 15V-676 This notice applies to your vehicle (VIN: xxxxxxxxxxxxxxxxx). manufacturing process. The A/C hose may come in contact with the engine exhaust manifold. Prolonged A/C hose contact with the engine exhaust manifold may result in a leak of the A/C refrigerant and/or A/C refrigerant oil. A/C refrigerant oil on a hot exhaust manifold could …

Not all exhaust manifolds are created equal. In fact, they aren’t even close. There seems to be some confusion in the industry as to which manifold is the best and where they are manufactured. The manifold extends from the cylinders to the exhaust pipe, collecting and moving exhaust away from the engine. Exhaust can be harmful to inhale, making it very important to have a fully functional exhaust manifold. The manifold consists of a series of pipes which connects to the cylinders and then consolidate in a central large pipe which vents to the exhaust pipe. About Us Our factory has

Find your stainless steel manifold easily amongst the 132 products from the leading brands (PARKER, Clippard, TESCOM,) on DirectIndustry, the industry specialist for your professional purchases. The process uses a precision mandrel positioned inside the tube during the bending process. This end result is a smooth, aesthetically pleasing appearance as it maintains the full inside tube diameter throughout the bend area. The use of mandrel bend pipes aids in reducing exhaust …

Second-Generation Catalytic Converter – the Dual-Bed System. Carmakers and Catalyst Companies Were Working on the Second-Generation Catalytic Converter – the Dual-Bed System. Air 2% O 2 Air Pump Exhaust Manifold Engine: Air/Fuel Calibration 13.5 to 14.5 NO Reduction Catalyst Oxidation Catalyst HC + CO OXIDATION AND NOx REDUCTION BY EXHAUST CATALYST REQUIRED … second case, the pipe radius of the entire exhaust manifold is considered as a design variable because the pipe radius is known important for the performance of the exhaust manifold …

manifold and exhaust manifold, the diameter of exhaust manifold, and the location of the switching valve. The diameter of the branch exhaust manifold is usually the - Bully Dog Exhaust Manifold Detroit (FL & WS) - Premium Rapid Flow Ceramic Coated Exhaust Manifolds for Freightliner/Western Star Series 60 12.7L & 14.0L '95-'03 These manifolds are the fastest flowing pieces available for the Series 60 12.7L and 14.0L Detroit engines. You will notice quicker turbo spool and higher power output and economy

Specialized in manufacturing presion Wholesales original diesel engine part exhaust manifold,Zhengzhou Sebon Heavy Machinery has mature technology of silica sol casting and water glass casting process. This report consists of three sections based on the discussion of advanced manufacturing processes and materials for the exhaust manifold, muffler box and tail pipe of an automotive exhaust system.

This assignment looks into the material selection and manufacturing process for an automotive exhaust system considering the operational requirements. Towards the end, the application of alternate material is also discussed. Working Requirements The maximum temperature in an automobile exhaust Chapter 16 Integrated Exhaust Manifold Type CylinderHeadStructureDesignforGravity Casting Process Ming Chen, Wenlei Yang, Tianyu Zhang, Donghang Liu

Manufacturing route for exhaust manifold The current manufacturing process for exhaust manifold by convert mould investment process. This process add more advantages to the part by preventing hot tears, vacuum assisted pouring, less chance of defects due to moulding, and greater casting yield. Wax pattern will be made and dipped into organic sand to create moulding. The organic moulds are In this paper a new manufacturing process for fabricating intake manifolds for Formula SAE race cars is presented. Specifically, an intake manifold system is fabricated in a two-step process…

The manifold collects the exhaust gases from the engine’s multiple cylinders and distributes them through the vehicle’s exhaust system. The interactions between the different cylinders and the pressure pattern in the channels influence the gas exchange process in the cylinders and the sound. Fabricated manifolds and manifold-converters are lighter than traditional cast manifolds, therefore manifold and exhaust manifold, the diameter of exhaust manifold, and the location of the switching valve. The diameter of the branch exhaust manifold is usually the

Exhaust Manifolds 10-4 Magazine

Variable geometry exhaust manifold turbocharging system. Exhaust insulation is a thermal insulator that keeps the heat inside the headers and exhaust system, giving two great benefits: lower underhood temperatures and better engine performance. Exhaust insulation limits how much heat can radiate from wrapped headers and exhaust, 90-806535970 1296 MECHANICAL INFORMATION - 3A-1 Engine Identification 4 Cylinder 73584 a a - Location of G.M. Engine Code MCM (Stern Drive) Code Rotation.

Method for manufacturing an exhaust manifold AP

High-quality Ductile Iron Clay Sand Castings Exhaust. tasked with researching, designing, and manufacturing header and muffler components with engine it is necessary to understand the combustion process. The four unique processes in an ignition cycle of a 4Вstroke engine are intake, compression, power, and exhaust. Figure 1 demonstrates the combustion cycle as (1) cylinder expansion for intake of air and fuel; (2) cylinder compression for, design constraints for cast-iron manifolds create internal air resistance making it difficult for exhaust gas to flow freely as it exits a cylinder, which robs the engine of horsepower..

Exhaust Manifold Design – FEA Approach Gopaal#1, in the design process of the exhaust manifold. The paper focuses on the application of constitutive equation to the thermo mechanical condition of a model based on isothermal data. Using the proposed model, the thermal stress analysis and life prediction of exhaust manifold made of 429EM stainless steel is done. A.K.M. Mohiuddin, … tasked with researching, designing, and manufacturing header and muffler components with engine it is necessary to understand the combustion process. The four unique processes in an ignition cycle of a 4Вstroke engine are intake, compression, power, and exhaust. Figure 1 demonstrates the combustion cycle as (1) cylinder expansion for intake of air and fuel; (2) cylinder compression for

tasked with researching, designing, and manufacturing header and muffler components with engine it is necessary to understand the combustion process. The four unique processes in an ignition cycle of a 4Вstroke engine are intake, compression, power, and exhaust. Figure 1 demonstrates the combustion cycle as (1) cylinder expansion for intake of air and fuel; (2) cylinder compression for The main cause of exhaust manifold cracks is defined by many authors as plasticity, which can be strongly influenced through changes to the local design.

A method of manufacturing an exhaust gas manifold, that includes metal exhaust pipes and metal flanges for attaching the pipe openings to corresponding internal combustion engine exhaust ports, employs a hybrid MIG welding process to reduce the occurrences of weld … Exhaust insulation is a thermal insulator that keeps the heat inside the headers and exhaust system, giving two great benefits: lower underhood temperatures and better engine performance. Exhaust insulation limits how much heat can radiate from wrapped headers and exhaust

The Cadic Corporation has established a mass production facility to produce near net shape stainless steel exhaust manifolds using Cadic's patented Convert Mold Process. The Cadic process converts ordinary mass-produced organic bonded sand molds into … This assignment looks into the material selection and manufacturing process for an automotive exhaust system considering the operational requirements. Towards the end, the application of alternate material is also discussed. Working Requirements The maximum temperature in an automobile exhaust

China Cast Iron Exhaust Manifold for Auto, Find details about China Manifold, Exhaust Manifold from Cast Iron Exhaust Manifold for Auto - Qingdao Seger Industrial Co., Ltd. Overview A new market study, titled "Global Automotive Exhaust Manifold Gasket Industry Market Analysis & Forecast 2018-2023 by Manufacturers, Regions, Type and Application, Forecast to 2023" has been featured on amplemarketreports.com.

- Bully Dog Exhaust Manifold Detroit (FL & WS) - Premium Rapid Flow Ceramic Coated Exhaust Manifolds for Freightliner/Western Star Series 60 12.7L & 14.0L '95-'03 These manifolds are the fastest flowing pieces available for the Series 60 12.7L and 14.0L Detroit engines. You will notice quicker turbo spool and higher power output and economy A method of manufacturing an exhaust gas manifold, that includes metal exhaust pipes and metal flanges for attaching the pipe openings to corresponding internal combustion engine exhaust ports, employs a hybrid MIG welding process to reduce the occurrences of weld …

The runners stem from the plenum and are connected to the cylinder head. Controls the air flow into the intake plenum. The plenum acts as a resonance chamber. 90-806535970 1296 MECHANICAL INFORMATION - 3A-1 Engine Identification 4 Cylinder 73584 a a - Location of G.M. Engine Code MCM (Stern Drive) Code Rotation

Specialized in manufacturing presion Wholesales original diesel engine part exhaust manifold,Zhengzhou Sebon Heavy Machinery has mature technology of silica sol casting and water glass casting process. Not all exhaust manifolds are created equal. In fact, they aren’t even close. There seems to be some confusion in the industry as to which manifold is the best and where they are manufactured.

A method of manufacturing an exhaust gas manifold, that includes metal exhaust pipes and metal flanges for attaching the pipe openings to corresponding internal combustion engine exhaust ports, employs a hybrid MIG welding process to reduce the occurrences of weld … Exhaust System Design & Manufacture Continuing on from the manifold, the under body section of the exhaust is specifically designed and built around the individual geometry of your vehicle. Not only does this allow us to create virtually any type of system configuration, we can work around non standard fitments and anomalies that may be present in your vehicle's lay out.

manifold and exhaust manifold, the diameter of exhaust manifold, and the location of the switching valve. The diameter of the branch exhaust manifold is usually the Second-Generation Catalytic Converter – the Dual-Bed System. Carmakers and Catalyst Companies Were Working on the Second-Generation Catalytic Converter – the Dual-Bed System. Air 2% O 2 Air Pump Exhaust Manifold Engine: Air/Fuel Calibration 13.5 to 14.5 NO Reduction Catalyst Oxidation Catalyst HC + CO OXIDATION AND NOx REDUCTION BY EXHAUST CATALYST REQUIRED …

(PDF) Coventry University EXHAUST MANIFOLD MUFFLER BOX

Exhaust manufacturing process YouTube. 2 1.3 Exhaust manifold and operating conditions The exhaust manifold primary function is to collect the exhaust from the individual cylinder heads and consolidate the exhausts through the turbo charger., Not all exhaust manifolds are created equal. In fact, they aren’t even close. There seems to be some confusion in the industry as to which manifold is the best and where they are manufactured..

Custom Stainless Steel Exhaust/Manifold Design and

Global Automotive Exhaust Manifold Gasket Industry Market. High-quality Ductile Iron Clay Sand Castings Exhaust Manifold for Agricultural Machinery, find complete details about High-quality Ductile Iron Clay Sand Castings Exhaust Manifold for Agricultural Machinery, ductile iron castings, Exhaust manifold, Agricultural Machinery parts - New Densen Co., Ltd. Not all exhaust manifolds are created equal. In fact, they aren’t even close. There seems to be some confusion in the industry as to which manifold is the best and where they are manufactured..

A method of manufacturing an exhaust gas manifold, that includes metal exhaust pipes and metal flanges for attaching the pipe openings to corresponding internal combustion engine exhaust ports, employs a hybrid MIG welding process to reduce the occurrences of weld … Exhaust manifold Intake manifold EGR valve EGR center pipe Diesel catalytic converter Exhaust Manifold To EGR valve To turbo- charger EGR pipe Intake manifold Intake manifold COMPONENTS LOCATOR EXHAUST SYSTEM LAYOUT Intake manifold Intake air (intercooler) EGR pipe (LH) EGR pipe (RH) Diesel catalytic converter → Muffler Exhaust manifold. EXHAUST SYSTEM ACTYON …

The main cause of exhaust manifold cracks is defined by many authors as plasticity, which can be strongly influenced through changes to the local design. The process uses a precision mandrel positioned inside the tube during the bending process. This end result is a smooth, aesthetically pleasing appearance as it maintains the full inside tube diameter throughout the bend area. The use of mandrel bend pipes aids in reducing exhaust …

The main goal of the certification process is to be issued a Supplemental Type Certificate (STC) and a Parts Manufacturing Approval (PMA) by the FAA. These allow us to sell and install our Tuned Exhaust … second case, the pipe radius of the entire exhaust manifold is considered as a design variable because the pipe radius is known important for the performance of the exhaust manifold …

Manufacturing workflows rely on the communication of clear data between all involved in design and production. PDF3D understands how important collaboration is to professionals working in aerospace and manufacturing, and has taken 3D PDF publishing and conversion … 90-806535970 1296 MECHANICAL INFORMATION - 3A-1 Engine Identification 4 Cylinder 73584 a a - Location of G.M. Engine Code MCM (Stern Drive) Code Rotation

Not all exhaust manifolds are created equal. In fact, they aren’t even close. There seems to be some confusion in the industry as to which manifold is the best and where they are manufactured. We use heat cycling, the process of repeated heating and cooling, to estimate the durability for the exhaust manifold. Wall heating Thermal fatigue We conduct durability and thermal fatigue tests to evaluate exhaust systems assembled onto the engine.

The runners stem from the plenum and are connected to the cylinder head. Controls the air flow into the intake plenum. The plenum acts as a resonance chamber. This assignment looks into the material selection and manufacturing process for an automotive exhaust system considering the operational requirements. Towards the end, the application of alternate material is also discussed. Working Requirements The maximum temperature in an automobile exhaust

IMPORTANT SAFETY RECALL R57 / NHTSA 15V-676 This notice applies to your vehicle (VIN: xxxxxxxxxxxxxxxxx). manufacturing process. The A/C hose may come in contact with the engine exhaust manifold. Prolonged A/C hose contact with the engine exhaust manifold may result in a leak of the A/C refrigerant and/or A/C refrigerant oil. A/C refrigerant oil on a hot exhaust manifold could … the exhaust manifold drives the turbocharger. The process of scavenging continues until the exhaust The process of scavenging continues until the exhaust valves close at 85° past TDC.

Exhaust Manifold Design – FEA Approach Gopaal#1, in the design process of the exhaust manifold. The paper focuses on the application of constitutive equation to the thermo mechanical condition of a model based on isothermal data. Using the proposed model, the thermal stress analysis and life prediction of exhaust manifold made of 429EM stainless steel is done. A.K.M. Mohiuddin, … design constraints for cast-iron manifolds create internal air resistance making it difficult for exhaust gas to flow freely as it exits a cylinder, which robs the engine of horsepower.

China Cast Iron Exhaust Manifold for Auto, Find details about China Manifold, Exhaust Manifold from Cast Iron Exhaust Manifold for Auto - Qingdao Seger Industrial Co., Ltd. A significant number of exhaust manifold, takedown piping and converter packaging design variations have emerged during the last years with varying performance and secondary e•ects.

change of the shape of the exhaust manifold is tried at least 10 times in design process. Consequently the elastic-plastic analysis is impractical in design process, and the linear elastic analysis for several candidates has been carried out to select one with a relatively low stress. The main cause of exhaust manifold cracks is defined by many authors as plasticity, which can be strongly influenced through changes to the local design.

Find your stainless steel manifold easily amongst the 132 products from the leading brands (PARKER, Clippard, TESCOM,) on DirectIndustry, the industry specialist for your professional purchases. Materials for Automotive Exhaust System S. Rajadurai1 Abstract— Durable exhaust system design, development and manufacturing is mandated for the vehicle to be competitive and comparative. Material selection for the exhaust system plays a vital role due to the increased warranty requirements and regulatory compliances. Physical, chemical and mechanical characteristics of the materials